GB

GB

5

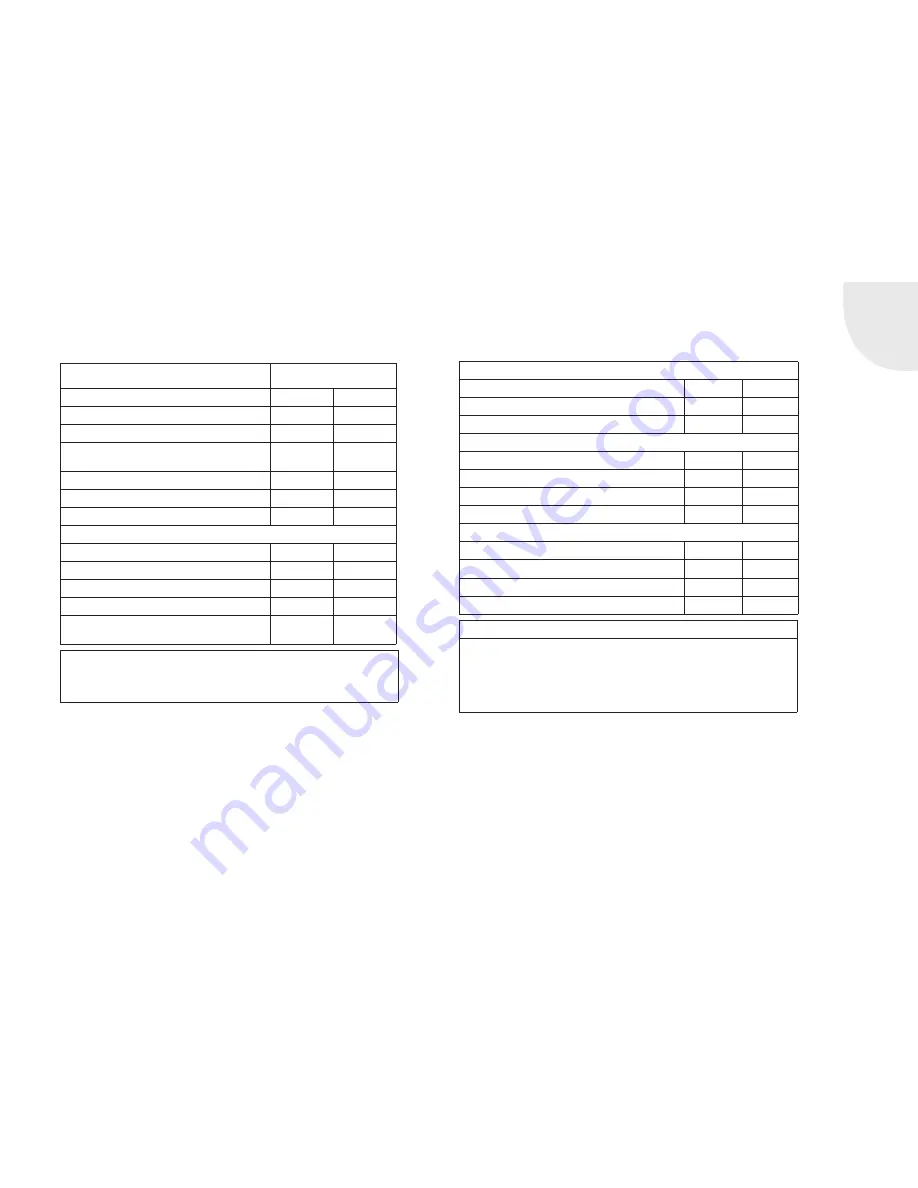

1.2 TECHNICAL DATA

Nova F

Weight (empty, without accessories)

190

kg

Nominal power with heat recovery section*

10

kW

Average heating gas temperature at the duct

355

°C

Average flue gas temperature downstream of the heat recovery

section

225

°C

Necessary min. delivery pressure**

12

Pa

Mass flow of flue gas

9,2

g/s

Wood feed quantity with nominal heat output/maximum

3,7

kg/70min

For other fill quantities:

Maximum possible feed quantity

8

kg/60min

Triplet values for 8 kg/60 min:

15

Pa

Average flue gas temperature at the duct

610

°C

Mass flow of flue gas

26

g/s

Average flue gas temperature at duct downstream of the heat

recovery section

395

°C

Between the triplet values after test (3.7 kg) and the max. fill quantity of 8 kg, interpolation is possible.

The draught length must be determined by the stove fitter based on the conditions, materials and

design. An estimate can be made using 50-80 K/m draught length.

This means that 610°C - 180°C = 430 K / 60 K = ~ 7 m

* The specified values represent the mean value over a combustion. These

values occur under test conditions with nominal heat output, if in 70 min

a quantity of approx. 2.7 kg of dry pieces of beech wood is burned and

the Spartherm metallic coasting temperature box (coasting temperature

unit) is installed.

** Pressure at the heating insert duct. Increased delivery pressures must be

reduced to less than 25 Pa through suitable measures, such as a draught

regulator or a damper.

Necessary minimum insulation thicknesses (Silca 250 KM)

Attachment wall (side / rear)

mm

100

Ceiling

mm

160

Setup floor (only under the metallic coasting temperature box

mm

20

Necessary minimum distances to heating chamber / components

Convection chamber (side / rear) to insert

mm

100

Insert to the setup floor

mm

140

Heat recovery section to the wall of the heating chamber

mm

100

Connecting line to the heating chamber ceiling

mm

200

Minimum distances in the radiation areas of the view pane

Flammable parts

mm

800

Flammable parts behind a radiation protection element

mm

400

Area of the non-flammable floor covering to the front

mm

500

Area of the non-flammable floor covering to the side

mm

300

Sheet metal radiation protection element

A sheet metal radiation protection element must be provided at the depth of the heating insert 1.0 m x

1.0 m 25 cm above the upper edge of the setup floor between the heating insert and the heating chamber

wall. Alternatively, the distance between the heating insert and heating chamber wall can be increased to

130 mm, and the insulation thickness can be increased to 120 mm. If the metallic coasting temperature

box (coasting temperature unit) is used, a sheet metal radiation protection element or insulation 20 mm

in thickness must be provided under the unit‘s base area.

The thicknesses of thermal insulation material are determined with open

air grates in the heating chamber, in accordance with DIN EN 13229. If a

closed heating chamber should be created, the thermal insulation material

thicknesses must be increased in the verification procedure. When using the

tested external firing unit, it must be fastened inside of other components

with suitable 100 mm fire protection insulation (see Material specification,

minimum insulation thicknesses).

Summary of Contents for Nova F

Page 1: ...GB Installation and Operating Manual Nova F...

Page 17: ...GB GB GB 17 NOTES...

Page 18: ...GB 18 NOTES...

Page 19: ...GB GB GB 19...