GB

8

• During this first burn, unpleasant odours may be produced. This is because

the anti-corrosion coating inside the combustion chamber is burning into

the steel surface. This is not a health hazard, but it does smell unpleasant.

Ensure sufficient ventilation in the installation space.

CAUTION! During a burning operation, the surfaces of the window

panes and cladding components can become very hot: Risk of burn

injuries!

3.2 HEATING AND FIRING

A good combustion requires correctly prepared fuel, the correct combustion

temperature for each burn-up phase and a suitable supply of oxygen to ena-

ble the system to function in an environmentally friendly and energy-efficient

manner.

3.2.1 IGNITION (DOWN BURN)

Principle: This firing method is a simple and effective way to reduce the

emissions from fire areas. The stack of wood burns downwards, from top to

bottom. With this firing method, all gases pass through the hot combustion

zone (flames) above the stack, enabling complete combustion to take place.

The wood further down is heated up gradually, gas flows outwards and burns

in the hot combustion zone. The result is combustion that runs much more

uniformly than when setting a fire from the bottom of the stack of wood.

Caution: The important thing about this process is that it prevents

rapid burn-up in a downwards direction. The lighting of firewood in

fire areas, and the correct stacking of that firewood together with

initial observation of the fire in respect of finding the most suitable

setting for combustion air all requires a certain level of experience.

Procedure:

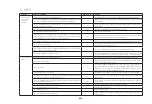

1. Open the combustion chamber door (swivel or slide upwards).

Depending on the length of firewood and the dimensions of the combustion

chamber, narrow fireplace inserts are filled with firewood that points towards

the front. Wide fireplace inserts are filled with the longitudinal side facing for-

wards, i.e. with the firewood arranged sideways. Note the wood feed quantities

defined in chapter „2.1.3 Quantities of wood”.

4. For the highest layer, sufficiently thin kindling is laid. Softwood is recom-

mended here (e.g. fir)

2. Start by stacking wood crosswise on the ash

left on the grate. Use the thicker firewood at

the bottom, with progressively thinner wood

towards the top of the stack.

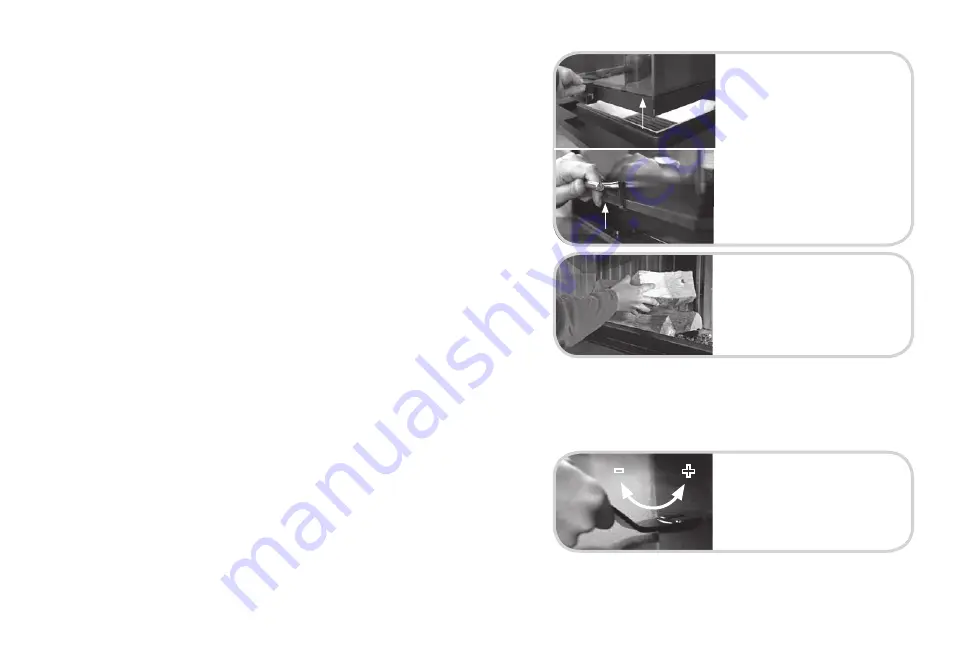

3. Open the combustion air inlet fully. Using the

‘cold hand’, turn the actuating lever into initial

combustion position (+).

+

-

- Vertically-oriented sliding equipment - do not

close door completely, but instead leave a gap

of 3 - 5 cm.

Premium insert

Standard insert

- With Premium inserts push the door upwards for

opening using the foldaway handle.