16

630359_5

A suitably sized hole will need to be drilled in the steel

convection air jacket to accommodate the flexible shaft to suit

the planned position of the control lever.

The fireplace must be installed on a

non-combustible base

that is suitably engineered to support the weight of the

appliance. We recommend a reinforced concrete slab (min.

100mm thick).Suitable

seismic restraint

must be provided.

This can easily be achieved by screwing or bolting the 4 feet

of the fireplace securely to the concrete slab.

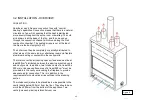

Combustion air

– In addition to providing cavity (convection)

intake air vents it is a requirement to also provide air for

combustion. If taking the combustion air from outside of the

building (Direct vent) through a Ø150mm (165mm OD) pipe

and into the appliance via the optional appliance adaptor

(recommended), ensure that the run of the Ø150mm pipe is

as short as possible and as unrestricted as possible.

Try to use 45° bends in lieu of 90° bends and restrict the total

number of bends to 2. If the pipe is in an area where

condensate may form on the outside then adequate provision

for lagging/insulation of the pipe outer should be planned.

Varia Bh-P7 inlet Varia ASh-P8, A-FDh-P8,

A-FDh-P8 & 2L/R 80h-P7 inlet

It is also advised to make provision for periodic cleaning of the

pipe inner by providing a “rodding eye” or other means of

access. Where the pipe terminates on the outside of the

building it should be suitably protected from water, foreign

matter ingress and rodent/bird/flying insect ingress.

The Ø150mm pipe run

within

the skamo enclosure board

enclosure should be made from a heat resistant material

(galvanised steel, stainless steel etc.). You may transition to

PVC pipe or similar 300mm after the pipe has exited the

Skamotec enclosure.

Providing a means to access each of the pipe joints for future

inspection and cleaning is recommended.

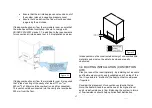

Considerations for positioning the combustion air intake

vent & pipe

•

Ensure that the chimney top and the air intake are

in the same pressure zone. Different zones could

cause problems particularly on windy days.

Figure 10

Summary of Contents for Varia 2L 80h-P7

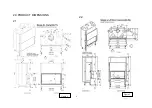

Page 5: ...5 630359_5 2 0 PRODUCT DIMENSIONS 2 1 2 2 Figure 1 Figure 2 ...

Page 6: ...6 630359_5 2 3 Figure 3 ...

Page 7: ...7 630359_5 2 4 Figure 4 ...

Page 8: ...8 630359_5 2 5 Figure 5 ...

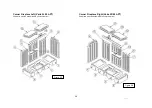

Page 23: ...23 630359_5 Corner L R Varia 2L 2R 80h P7 Double Sided Varia A FDh P8 Figure 23 Figure 24 ...

Page 26: ...26 630359_5 3 7 EXAMPLE OF CAVITY CONSTRUCTION Figure 30 Figure 31 ...

Page 51: ...51 630359_5 ...

Page 52: ...52 630359_5 Data Plate Installer Adhere duplicate data plate here ...