ORBITAL

12

Training

It is the responsibility of the Spearhead dealer to provide instruction on the

safe installation, operation and maintenance of the machine in the first

instance. Further training is available from Spearhead Machinery Ltd on

request, at cost.

Tractor Requirements

•

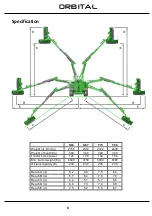

Check your Tractor size and minimum weight on the Specification table

•

Before hitching, ensure position control is selected. Do not attempt to

hitch in draft control.

•

Set wheel width as wide as possible.

•

Ballast weight is to be fitted within tract

or manufacturer’s recommended

requirements

•

Check chains and stabilisers must be in good working order to hold the

machine firmly. Do not operate without checking chains and stabilisers

are tight.

•

Spearhead particularly recommend ‘turn buckle’ type stabiliser.

•

Set linkage lift rods to an equal length

•

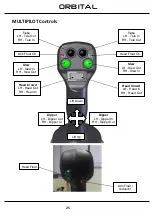

Certain machines require a 12V fused electric supply that is controlled

by the tractor’s ignition key.

•

Spearhead particularly recommend three point linkage of ball end type,

we do not advise the use of claw type hitching. The quick release

latches should be checked, if worn or insecure they may cause

accidental damage or personal injury if the machine becomes

detached.

•

Ensure tractor link arms can be isolated from accidental lifting.

Lighting Kits

For additional safety, rear mounted lighting kits are already fitted as standard.

For more detailed information, contact the Department of Transport or your

local Highways Authority.

Pallet Fork Lifting Points