8999146EN: v1 26/02/2020

26

Original instructions (ENGLISH)

Website: www.spearheadmachinery.com

3

Machine Preparation

3.1 Tractor Requirements;

Before fitting the machine to the tractor ensure that specification of the tractor meets the requirements listed

below.

3.2

Tractor Checks

Availability of tractor hydraulic service where the available flow is. 84-87 litres per minute at 210 bar for

Twiga reach arms. 45 litres per minute at 210 bar for Twiga Carrier arms.

A suitable mounting interface to the tractor is available.

Once the attachment is mounted to the reach arm and the tractor is correctly ballasted ensure that the

maximum axle loads for the tractor have not been exceeded. Failure to meet this requirement may

render the operator liable for infringement of public highway regulations.

Ensure that the tyres fitted to the tractor are correctly rated for the total working weight. NOTE: When

the attachment is deployed in work at the furthest reach the load on the rear tyre on the cutting side

increases significantly.

Spearhead does not endorse the use of water ballast within tyres as this can have adverse effects on

fore aft stability at speed.

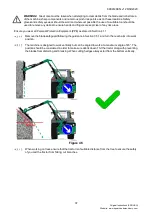

3.3 Lifting The Machine

3.3.1

Lifting Equipment

Suitable overhead lifting equipment with a minimum Safe Working Load (SWL) in excess of the

machine’s

overall weight should be used for handling the machine. Ensure the machine is kept balanced and level at all

times during the lifting procedure. All operatives and bystanders must remain at a safe distance from the raised

machine.

3.3.2

Lifting Points

Machines are equipped with 2 lifting points fitted with shackles.

Lifting gear must be evenly attached to both lifting points to ensure machine is balanced and stable during lifting.

Keep clear of the raised machine at all times.

Model Weights

SP15 Trisaw

180kg (397lbs)

SP20 Quadsaw

220kg (485lbs)

SP25 Quadsaw

255kg (562lbs)

Figure 3.1