8999146EN: v1 26/02/2020

16

Original instructions (ENGLISH)

Website: www.spearheadmachinery.com

2.4

Noise

The equivalent daily personal noise exposure from this machine, measured at the operator's ear, is 90dB when

used in conditions where the load fluctuates between zero and maximum. This applies when the machine is

attached to a tractor fitted with a quiet cab and used in accordance with the operating instructions in a generally

open environment. At equivalent daily noise exposure levels of between 85 and 90dB, suitable ear protectors

are recommended.

2.5

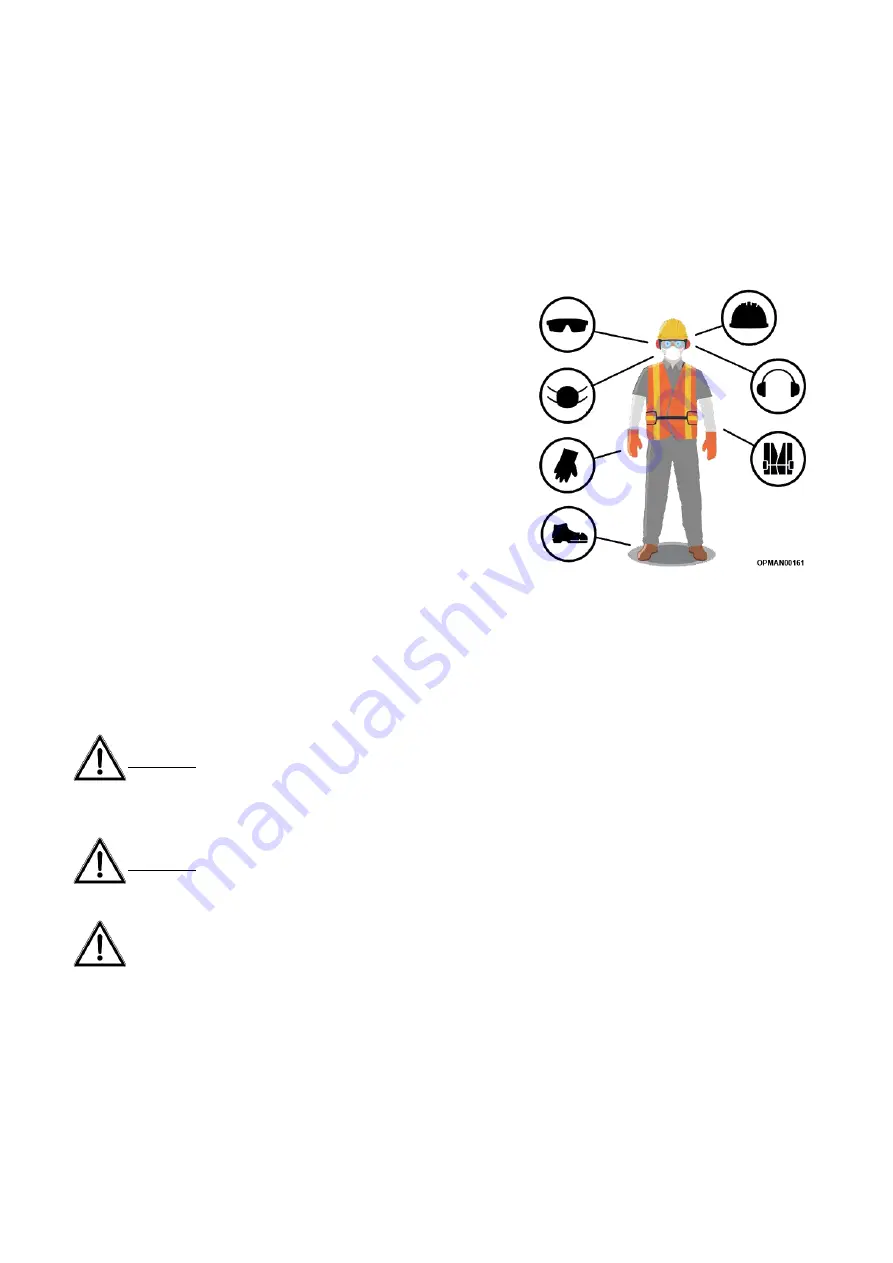

Personal Protective Equipment

Operators should be wearing sufficient personal protection

equipment (PPE) to protect them from hearing, respiratory and

impact damages.

When working in an unsealed cab or where windows and apertures

are open to the environment, operators are advised to wear suitable

eye and ear protection, a facemask (depending on conditions) and

eye protection.

When handling cutting surfaces or hydraulic equipment, operators

are advised to wear suitable gloves.

When clearing blockages, clearing wire, or working with pressurised

hydraulic components, operators are advised to wear suitable eye

protection and suitable gloves.

Ensure that non-baggy clothing is worn to reduce the chance of

entanglement and snagging on components.

Figure 2.4- PPE Items

When working at the work

site, but off the tractor unit, operators are advised to wear a ‘high-viz’ garment.

2.6

Cab Guarding

DANGER!

For safe operation it is essential that that all guards must be kept in position on the machine

whenever the machine is running. Spearhead Machinery disclaim all responsibility for any

damage or injury arising as a result of guards being removed, or of guards other than of

Spearhead manufacture having been fitted, or of operation of the machine other than in

accordance with these instructions.

DANGER!

When hedge cutting a mesh guard must be fitted to the side window of the tractor cab. Cabs

without laminated or toughened glass must also be fitted with a laminated glass or

polycarbonate shield in addition to the welded mesh guard.

WARNING!

Inspect guards twice daily or immediately damage is suspected.

Always replace guards that have damage or wear which could impair their performance

The sawblade itself is a unique way to cut compared to the rest of the Spearhead range. The sawblades run in

the cowl with very little guarding due to the way the discs are designed to operate.

It is important that the belt guard is in position when the machine is in work. When the machine is out of work in

storage or during transit, it is important to reinstall the sawblade guard provided with the machine in order to

ensure bystanders do not get injured along with ensuring the sawblades remain intact and undamaged when not

in use. See Section 3.5.1.