8999146EN: v1 26/02/2020

39

Original instructions (ENGLISH)

Website: www.spearheadmachinery.com

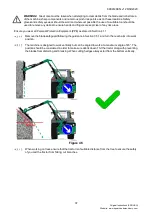

The machine should NEVER be used at angles which could cause debris to get thrown towards the

tractor or other bystanders, vehicles or buildings.

Figure 4.9

4.4

Beginning Work

4.4.1

Pre-start Checks

IMPORTANT:

Starting the machine should only be carried out once the machine and work site has been

inspected and deemed safe and all other safety cautions have been adhered to.

At every opportunity and before getting into the cab and starting the engine perform the following inspections;

Check that the attachment is free from obstructions especially pieces of wire.

Check that all blades are in good condition and securely attached.

Check that all fixed guards are in their correct place and in good condition.

Check that the tractor is equipped to deliver the correct hydraulic flow and pressure for the attachment.

Refer to the operator manuals for the tractor and reach arm.

4.4.2

Starting The Sawblade

Once pre-start checks have been carried out, the machine is can then be started.

Start the machine at low oil flow (low rpm). If the machine is starting from cold, warm the machine up

for approximately 15 minutes to heat up the oil.

Ensure that the machine is never started in material where it will have to work under load.

Slowly increase rpm until the correct oil amount is reached.

Operate and adjust the cowl angling ram or adjuster to the required working angle. The ram may be

operated during work to make minor angling adjustments, but is recommended to stop work before

making major adjustments to the cutting angle.

Never attempt to restart the attachment if there is something strained/wedged in the machine. Stop the

machine and the vehicle engine. Relieve hydraulic pressure before inspecting or trying to address the

problem. Remove the ignition key and engage the handbrake. Only then it is safe to remove the

wedged in material. Always wear safety glasses and work gloves.

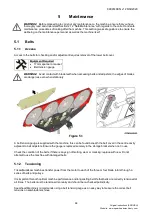

4.4.3

Stopping The Sawblade

Reduce engine RPM gradually to idle and stop the machine.

Never increase or reduce the oil amount too fast. This will damage the hydraulic system on a long-

term basis.

When you are finished working, stop the engine, remove the ignition key and engage the handbrake,

leaving the machine in a safe and secure position. Always wear safety glasses and work gloves. Refit

safeguard. Beware of sharp cutting parts!

Always show consideration for other road users during transportation.