8999146EN: v1 26/02/2020

41

Original instructions (ENGLISH)

Website: www.spearheadmachinery.com

4.6

Transporting The Sawblade

In order to safely transport the reach arm mower and attachment when not in work with the tractor requires the

operator to have a thorough knowledge and experience of the tractor they’re using and safety precautions they

should take.

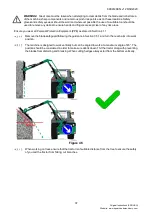

Figure 4.10

After finishing work, the arm with the attached sawblade needs to be pulled close to the vehicle where it takes up

the least room.

Once the reach arm is placed in the transport position:

Close the outer arm in fully to the inner arm and slew the arm from work position into transport

position.

The inner arm needs to be lifted until the transportation stop is met or close to the vehicle.

Angle the attachment in order to take up the least amount of space.

For Spearhead machines with slewing ability the reach arm should be slewed behind the tractor. Be

mindful, if the reach arm is lifted to the transportation stop that it doesn’t hit the cab of the vehicle or will

hit the cab during transportation.

All hoses are sufficiently clear of the tyres to prevent contact during bounce and sway on braking,

turning and undulating ground.

It is an essential requirement that when the machine is in the transport position all the isolator valves

are closed.

Otherwise:

Ensure the tractor has been properly serviced and maintained. Do not operate the tractor with

weak/faulty brakes or worn tyres.

Ensure the tractor has the capacity to handle the weight of the reach arm and attachment.

Failure to have at least 20% sufficient load over the front axle or to drive at inappropriate speeds on

undulating terrain may result in a loss of directional control.

Ensure the tractor operating and reach arm controls are set for safe transport. Consult the tractor and

reach arm manufacturers operators manual.