8999146EN: v1 26/02/2020

44

Original instructions (ENGLISH)

Website: www.spearheadmachinery.com

5

Maintenance

WARNING!

Before proceeding to carry out any maintenance on the machine, ensure that you have

thoroughly read and understand Section 2.12

“Safe Maintenance” with regards to the correct and safe

maintenance procedures of looking after the machine. This section gives safe guidance to ensure the

wellbeing on the maintenance personnel as well as the machine itself.

5.1

Belts

5.1.1

Access

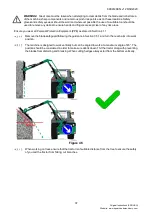

Access to the belts for checking and/or adjustment requires removal of the lower belt cover.

Equipment Required

•

17mm spanner or socket

•

Belt tension gauge

WARNING!

Avoid contact with blade teeth when accessing belts and adjusters; the edges of blades

are dangerous even when stationary.

Figure 5.1

A belt tension gauge is supplied with the machine, this can be found beneath the belt cover in the centre cavity

adjacent to belt adjusters. Ensure the gauge is replaced securely in the storage bracket when not in use.

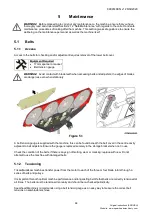

Check the condition of the belts, if there is any sign of melting, wear or cracking; replace with new. Do not

attempt to use the machine with damaged belts.

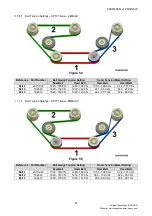

5.1.2

Tensioning

Trisaw/Quadsaw machines transfer power from the motor to each of the three or four blade rotors through a

series of belts and pulleys.

It is important for both optimal machine performance and long-lasting belt life that belts are correctly tensioned at

all times. The belts must be tensioned manually and should be re-checked periodically.

Spearhead Machinery recommends using a belt tension gauge as an easy way to measure the correct belt

tensions on sawblade machines.