OPERATING INSTRUCTIONS

18

3

Transportation and Storage

3.1

Transportation

The transportation of the complete unit has to

be effected correctly. For pumps with base

plate and motor you must not suspend the

pump from the ring loop on the motor.

3.2

Storage

It is advisable to store the unit in dry conditions.

The pump has to be protected against penetra-

tion of dirty parts.

4

Description of the Product

4.1

Construction

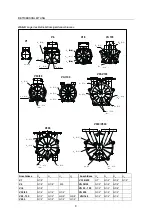

SPECK liquid ring vacuum pumps of the

V / VI / VG / VGI - type are closed coupled

pumps. The motor is also serving as pump

shaft. The shaft sealing is effected by a single

acting mechanical seal.

The pump is of simple, robust construction.

4.2

Function

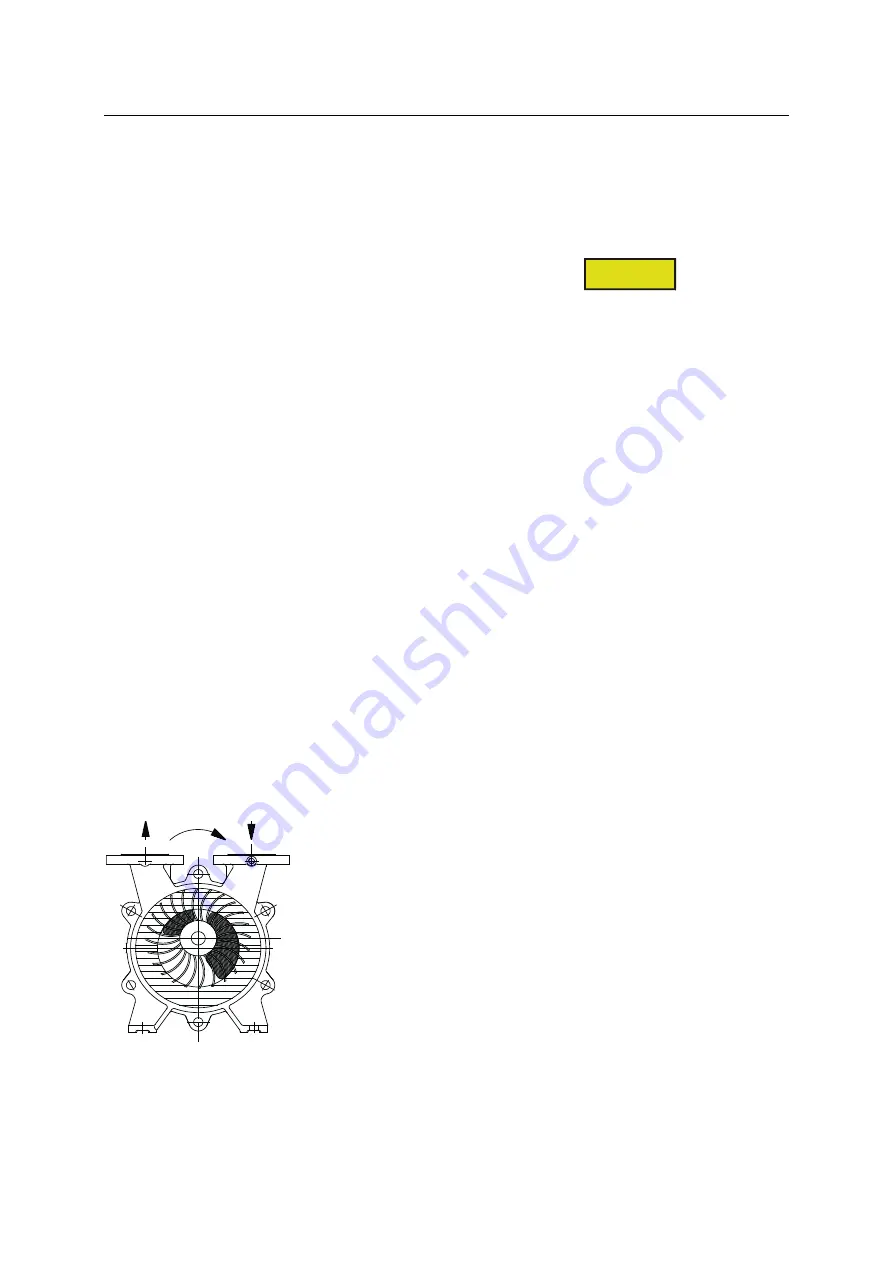

The liquid ring rotates inside the working area

eccentrically to the shaft. The impeller trans-

mits the drive performance by the circulating

liquid ring as compression power to the gas to

be delivered. This produces low pulsation

compression.

Illustr 1

: function

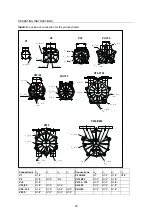

The service liquid - normally water - must be

added and cooled continuously. This dissi-

pates the resulting compression heat and adds

liquid to the ring, since part of the liquid is

continuously dissipated along with the gas on

the pressure side. The liquid can be separated

from the gas in a discharge separator at-

tached.

5

Set up and Installation

CAUTION

The non-observation of all safety informa-

tions given under “5 Setting

up/Installation” shall invalidate any claims

of warranty including claims for compensa-

tion of damages.

5.1

Place of Installation

Always choose a place of installation, where

pump is easily accessible.

5.2

Setting-up the Unit

The vacuum pump has to be screwed with the

motor feet

without warping

to the base plate

or a plain base plate.

If low vibration running is a high priority, the

unit must be fixed to a vibration insulated

foundation (with no fixed connection between

the base plate and the foundation or the

equipment frame).

If the floor is uneven, chock up the base

plate/foot with appropriate flat objects, cement

or similar. Any warping of the base plate badly

affects the alignment of the coupling. It is

advisable to check the alignment of the cou-

pling with a ruler or a gauge (before and) after

tightening the base plate.

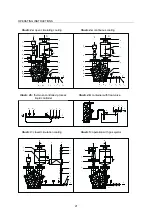

The mounting position is to be horizontal. The

suction and discharge fitting of the pump

should be positioned vertically facing upward

or horizontally to the right (view towards

pump). The horizontal discharge connection is

situated at bottom. In order to avoid the pump

to be drained out, when not being used, the

pressure pipe has to be raised up to the middle

of the shaft.

5.3

Pipes

Suction and discharge connections as well as

the connection for the operating liquid are

sealed, when the pumps is supplied, in order

to avoid the penetration of any foreign bodies.

The seals are not to be removed before the

pipes are fitted.