OPERATING INSTRUCTIONS

20

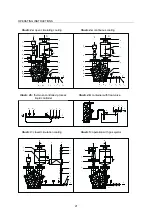

5.5.3 Continuous

cooling

The continuous cooling is effected, if sufficient

liquid is available, for which it is not important

being recycled as operating liquid.

The setting up is to be effected according to

illustr. 4a.

The connection

U

U

will be sealed.

The operating liquid

B

consists of clean liquid

F

. The required pressure of clean liquid should

not considerably exceed 0 bar (atmospherical

pressure).

If the pressure of clean liquid is considerably

fluctuating (from time to time an over pressure

of 0,2 bar will be exceeded), it is useful to

provide a pressure reducing valve

R

F3

(

illustr.

2b

) or to lead the clean liquid into a container

b

with float valve

R

F1

. The pump primes the

operating liquid

B

out of this container (

illustr.

4b

). The level of the liquid should be in the

middle of the shaft.

In case the gas and the liquid have not to be

discharged separately, a liquid separator may

be omitted. It would then be sufficient to install

a pipe

I

D

, leading to a discharge sink.

5.5.4 Execution with gas ejector

In order to achieve certain operating points the

vacuum pump will be provided with a gas

ejector pump.

5.6

Setting up of the unit

A side mounted liquid separator has to be

installed thus that the liquid discharge is at the

same level as the shaft.

The liquid separator is mounted to the dis-

charge nozzle of the pump.

.

Select an appropriate operating mode such

that as little fresh liquid as possible is needed.

Setting up schema

Descriptions to

illustrations 2a - 5

m

B

Mano vacuum meter

m

D

manometer A

discharge liquid

B operating

liquid

F clean

liquid

K cooling

liquid

T expanding

agent

U circulating

liquid

N liquid

level

S medium

suction

side

D

medium discharge side

P

liquid ring vacuum pump

PB circulating

pump

a liquid

separator

b

clean liquid container

g

gas ejector pump

h ventilating

device

w heat

exchanger

V

F

shut-off

valve

V

K

shut-off

valve

V

S

non-return

valve

r

B

regulating

valve

r

F

regulating

valve

r

F1

regulating valve (float valve)

r

F2

regulating valve (thermostatic)

r

F3

regulating valve (reducing regulator)

I

B

pipe for operating liquid

I

F

pipe for clean liquid

I

G

pipe for cavitation protection

I

K

pipe for cooling liquid

I

S

suction

pipe

I

D

discharge

pipe

I

U

circulating

pipe

m

t

thermometer

m

t1

temperature probe to r

F2

U

A

liquid

discharge

U

B

connection for operating liquid

U

C

cavitation

protection

U

V

connection for control valve

U

S

connection for suction pipe

D

U

connection for discharge pipe

U

U

connection for circulating liquid

U

e

discharge

U

se

connection for draining pipe

U

sn

connection for sensor

U

L

connection for ventilation device