7

XR 50

V3.1 | May 02, 2016

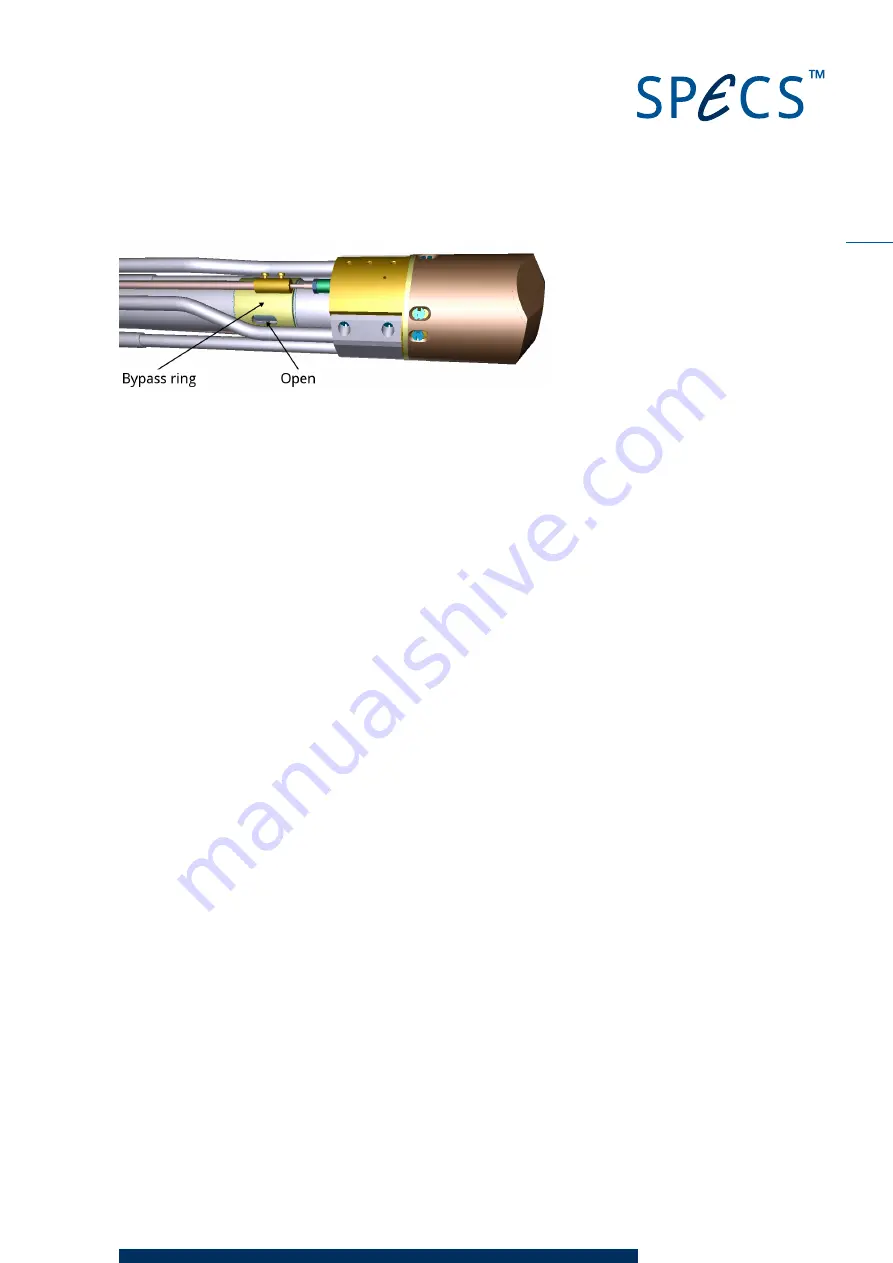

Figure 2: Bypass ring in the open position

2.2.3

Z-Drive (Optional)

The XR 50 can be supplied with an optional Z-drive so that the source can be retracted from its

working position. This protects the head of the source (and its aluminium window) from dam-

age, e.g. from sputtering, or prevents the source from obstructing other equipment.

Note

The cooling system of the XR 50 is efficient—there is generally no need to retract the XR 50 in

order to reduce thermal strain on other equipment.

The Z-drive is available in 50 mm and 100 mm versions.

In order to prevent collisions between the HV shield and the Z-drive, a spacer is provided. This

is a 40 mm tube with a DN40CF flange at each end, one flange being rotatable. You should

attach the items to the chamber in the following order:

Z-drive

Spacer

Source

2.3

Bakeout

The XR 50 can be baked up to 180 °C. Remember to observe the maximum bakeout tem-

perature for other equipment on your system. Do not use heating tapes or jackets for the

bakeout—these can lead to hotspots which can damage the source and cause uneven baking

conditions which may lead to pressure bursts and arcing during operation.

Before baking out, observe the following points:

Unplug the grounding cables.

Remove the protection cap and supporting frame.

Remove all cables and water connections from the XR 50.

Blow any water out of the source using compressed air.

Summary of Contents for XR 50

Page 1: ...XR 50 XR 50 NAP X Ray Source User Manual V3 1 May 02 2016...

Page 6: ...XR 50 V3 1 May 02 2016 This page intentionally left vi...

Page 20: ...XR 50 V3 1 May 02 2016 This page intentionally left 14...

Page 30: ...XR 50 V3 1 May 02 2016 This page intentionally left 24...

Page 38: ...XR 50 V3 1 May 02 2016 This page intentionally left 32...

Page 46: ...XR 50 V3 1 May 02 2016 This page intentionally left 40...

Page 58: ......