XR 50

V3.1 | May 02, 2016

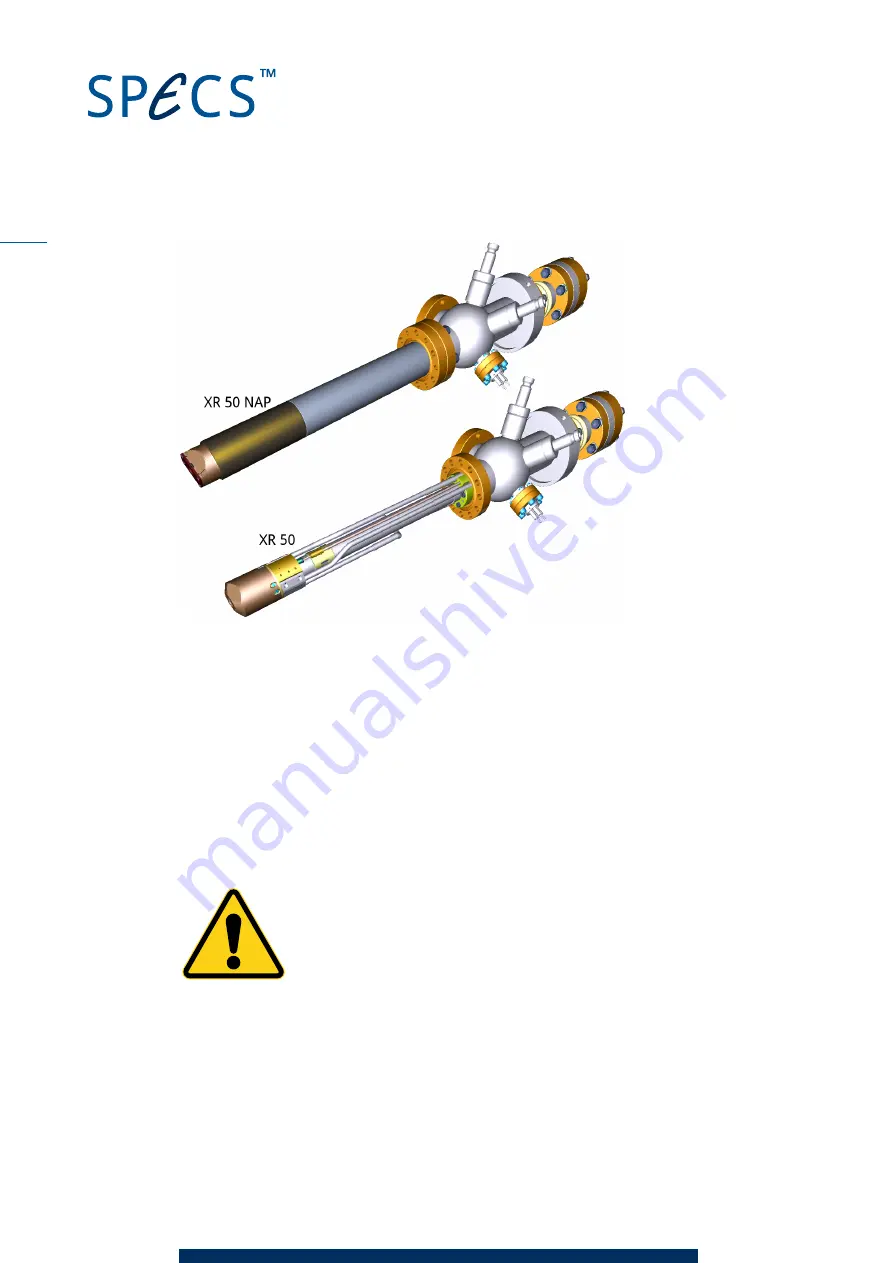

Figure 27: Construction of the XR 50 HP and XR 50

A.2

Operation

You need to attach a 60 l/s turbopump to the pumping port on the XR 50. This allows a max-

imum pressure in the analysis chamber of 25 mbar. We recommend that you fit a bypass with a

valve between the source and chamber. This valve should be open when the chamber is not

being used for high pressure measurements. This is particularly important when venting the

chamber, in order to prevent a pressure difference across the window.

When degassing the filament, make sure that the cooling water is running. This ensures that

the sheath does not heat up, and thereby prevents any damage to the Viton O-ring.

Caution!

The silicone nitride window on the source is vital in separating the interior of

the X-ray source from the analysis chamber! Tears or perforations in the win-

dow will expose the X-ray source to the elevated pressure in the chamber,

potentially causing damage to the source!

If a high voltage spark occurs during operation, there is a strong possibility that the silicone

nitride window will be damaged. In order to avoid this, we recommend that you use a maximum

anode voltage of 12 kV. This considerably reduces the probability of sparking.

46

Summary of Contents for XR 50

Page 1: ...XR 50 XR 50 NAP X Ray Source User Manual V3 1 May 02 2016...

Page 6: ...XR 50 V3 1 May 02 2016 This page intentionally left vi...

Page 20: ...XR 50 V3 1 May 02 2016 This page intentionally left 14...

Page 30: ...XR 50 V3 1 May 02 2016 This page intentionally left 24...

Page 38: ...XR 50 V3 1 May 02 2016 This page intentionally left 32...

Page 46: ...XR 50 V3 1 May 02 2016 This page intentionally left 40...

Page 58: ......