9

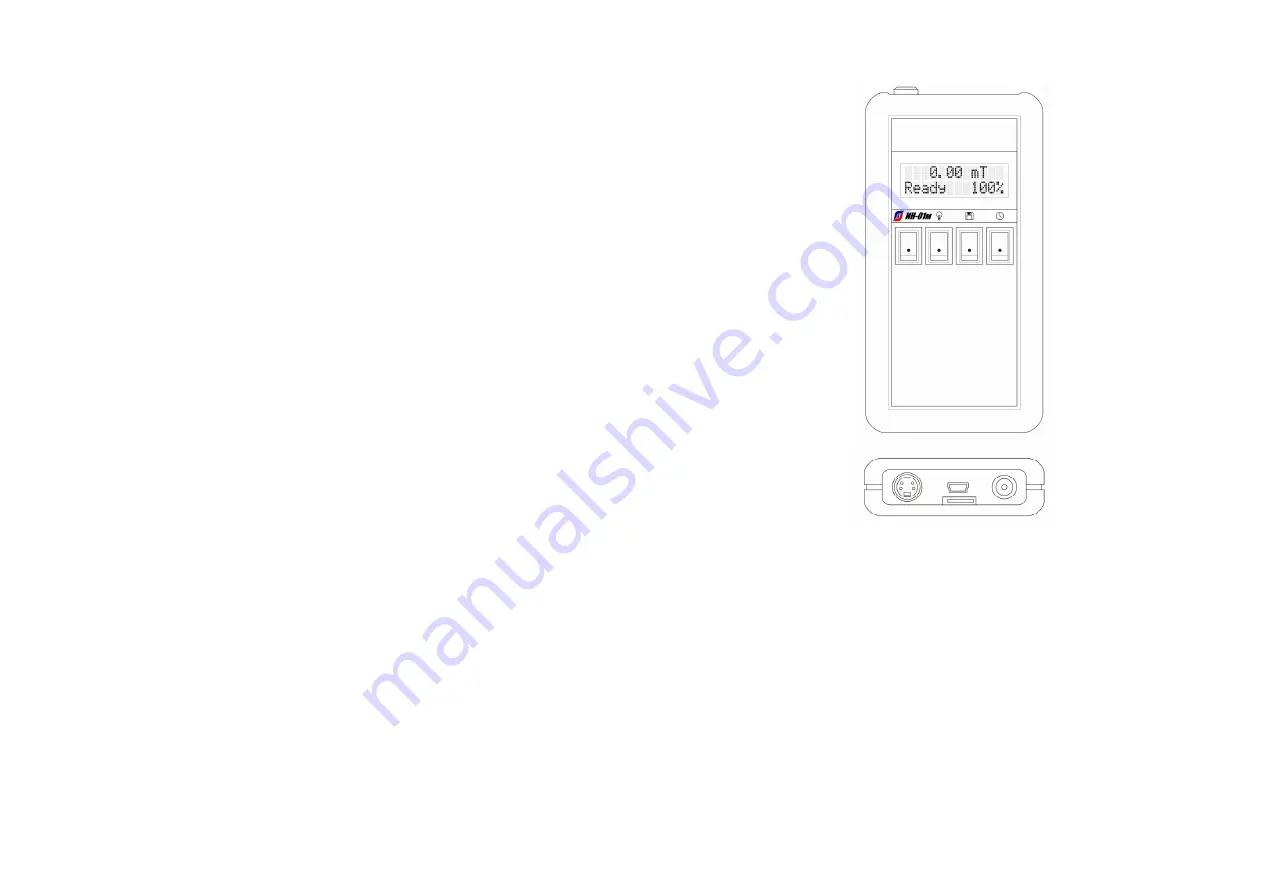

3.3.1. The stress indicator consists of a magnetizing

device 1, an electronic unit 2, and a sensor 3 connected to the

electronic unit via a connector.

3.3.2. On the front panel of the electronic unit, there is

a digital liquid crystal display 4, a power button 5, a button for

turning on the device's screen backlight 6, a button for

recording the measurement in memory 7, and a button for

displaying the current date and time 8 (Fig.3.3).

3.3.3. The battery cover is located on the back of the

electronic unit housing. To remove the battery from the battery

compartment, press the battery cover slightly and slide it

down.

3.3.4. In the upper part of the electronic unit housing,

there is a panel of connectors (Fig.3.3).

3.3.4.1. Connector 9 is used for connecting to the

electronic unit of the Sensor.

3.3.4.2. Connector 10 is used for placing a memory

card (flash card) in the electronic block.

3.3.4.3. The mini-USB 11 connector is used for

transmitting measured data via a cable to a personal computer

and receiving service information from the computer.

3.3.4.4. Connector 12 is used to connect the charger's

network adapter to the electronic unit for recharging the

battery (battery).

3.4. The purpose of the controls of stress indicator

3.4.1. The liquid crystal display 4 is used to display

information during the operation of the stress indicator.

3.4.2. Button 5 is used to turn on the electric power of

the stress indicator.

When you turn on button 5 information about the type

of stress indicator appears on its screen for a short time and its

serial number (Fig.3.4 a).

10

Fig.3.3. Location of controls and connectors of the

electronic unit of IN-01m the metal stress indicator

4 – alphanumeric liquid crystal display, 5 – power

button, 6 – screen backlight button, 7 – button to perform

recording measurements in memory, 8 – button for displaying

the date and time, 9 – sensor connector, 10 – memory card

slot, 11 – mini-USB connector, 12 – connector for charger

network adapter.

After setting the measurement mode, the stress

indicator screen displays a digital indication of the output

signal of the sensor (mT or MPa) the battery charge level of

the stress indicator in % , and its ready state (Fig.3.4 b).

4

5 6 7 8

9

10

11

12