6

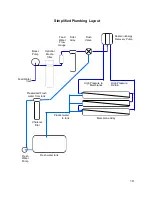

The Spectra Cabo-10,000 watermaker is designed for use in seagoing vessels or

platforms. Feed water must be supplied to the system a minimum of 20 gpm (76lpm)

at ≈20psi (1.4 Bar) pressure. The machine separates the feed water into two

streams; product and brine. The brine stream contains the dissolved solids removed

from the product water. Brine flow may be as high as 13 gpm (50L/min) and should be

discharged above the waterline. The system requires a small amount of back pressure

on the brine stream so plumb the discharge accordingly. Long runs in solid tubing will

require a vacuum break so as to not create any suction at the brine discharge.

Cabo 10,000

frame is constructed of powder coated 304 stainless steel and must be

positively fixed in place. includes the Spectra Pearson Pump, Motor and Belt drive

system coupled to three 8” x 40” seawater membranes. All high pressure connections

between the membranes and the pump come pre-assembled and tested. The high

pressure hoses use 1” JIC 37 deg. flare fittings.

20” Pre-filter Housings

are two 5 micron filter

housings plumbed in parallel. The filter housing

lids have a spring loaded “purge” button to

released air from the filters. Do not install the

filters above any electrical devices as some water

will be spilled when changing the filters or purging

air.

Note that filter housings should always be

tightened hand tight, do not use the wrench. If the

housing leaks when hand tightened then the o-

ring needs to be cleaned and greased (silicone

grease only). A small amount of silicone grease

on the threads will also help the housing to seal by

hand tightening.

Boost Pump assembly

is to be

installed below the water line in

seagoing vessels. The pump will fail if

there is any suction on the inlet so be

sure the pump is completely flooded at

all times. Land based systems will be

supplied with Jet pump (that have a

suction head limit of 10 ft.) or a well

pump based on the specific customer

requirements.

Introduction to your System

Summary of Contents for CABO 10,000

Page 2: ...2...

Page 4: ...4...

Page 21: ...21...

Page 22: ...22 Connector Pin Locations and speed control settings...

Page 23: ...23 Boost Pump Speed control...

Page 25: ...25...