SpectraPure

®

SpectraPure

®

Inc.

480.894.5437 Call us toll-free 1.800.685.2783

2167 East Fifth St, Tempe, Arizona 85281

3

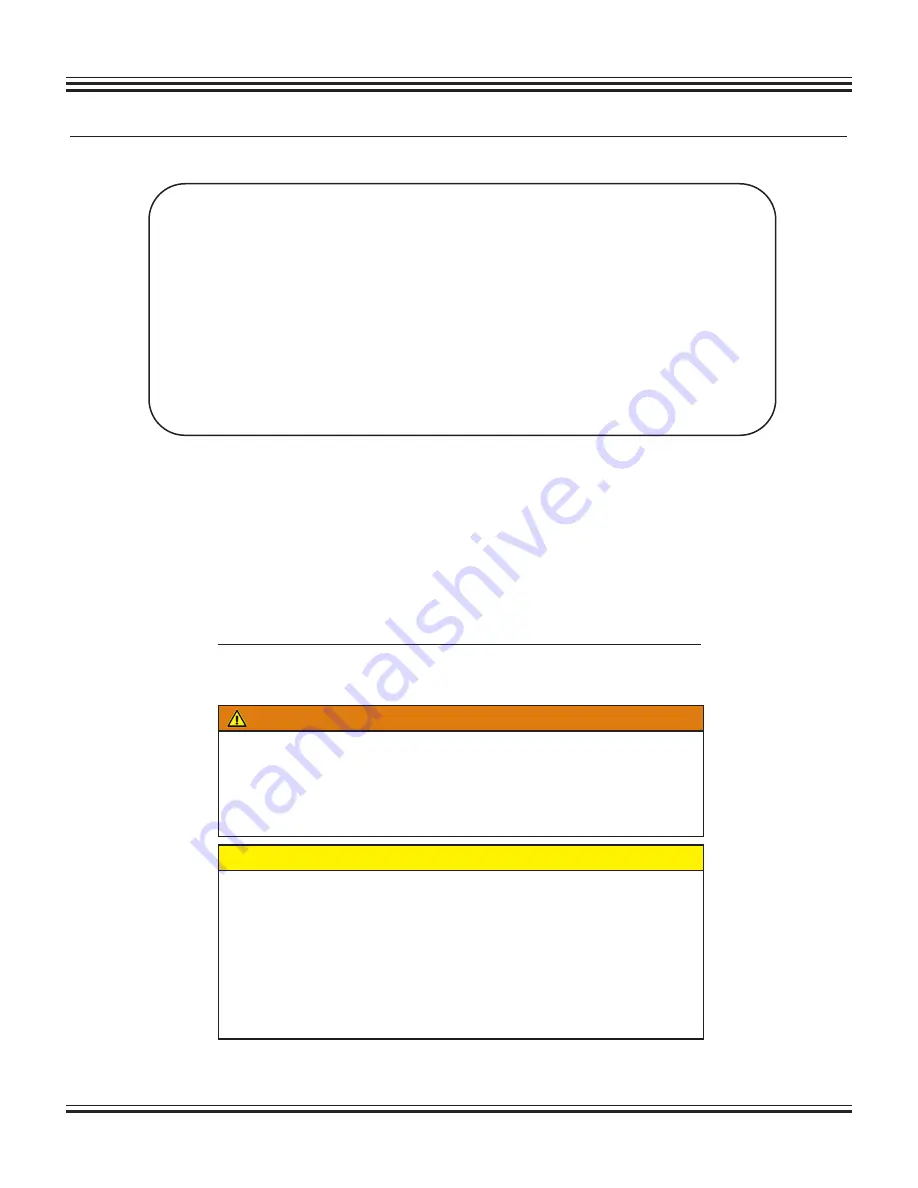

OPERATIONAL SPECIFICATIONS

NOTE: MOST MUNICIPAL WATER SUPPLIES MEET THE ABOVE REQUIREMENTS. IF WELL WATER IS USED,

PLEASE MAKE SURE THAT YOU OBTAIN A WATER TEST BEFORE INSTALLATION.

NOTE: THE OPERATING PRESSURE IN YOUR HOME SHOULD BE TESTED OVER A 24 HOUR PERIOD TO OBTAIN

THE MAXIMUM PRESSURE. IF IT IS ABOVE 80 PSI THEN A PRESSURE REGULATOR WILL BE REQUIRED.

RO Feed water requirements

Operating Pressure:

40-80 psi (2.75- 5.5 bar)

pH Range:

3-11

Max. Temperature:

113°F (45°C)

Max. Feed Turbidity:

1.0 NTU

Max. Silt Density Index:

5.0 (based on 15 min. test time)

Maximum Chlorine:

< 0.1 ppm

Maximum TDS:

2000 ppm

Maximum Hardness:

10 grains (170 ppm as CaCO

3

)

Maximum Iron:

< 0.1 ppm.

Maximum Manganese:

< 0.1 ppm.

Maximum Hydrogen Sulfide:

0 ppm

Langelier Saturation Index (LSI):

must be negative

SAFETY PRECAUTIONS:

Failure to follow the listed precautions may result in bodily injury, equipment

damage, and/or loss of warranty coverage.

WARNING

•

Do not mount your water purification system above an electrical outlet.

Leakage may cause the outlet to short circuit and could possibly result

in bodily injury.

•

This system is meant for use with potable water sources. Do not use

with water that is microbiologically unsafe.

CAUTION

•

Install in compliance with state and local electrical and plumbing

codes.

•

Do not install where system will be exposed to direct sunlight.

•

Protect against freezing temperatures and temperatures over 113

°F/45 °C which may damage components.

•

When using in conjunction with an open reservoir, user should install

bulkhead fitting and tube to drain at highest point of reservoir to avoid

catastrophic flooding.