SpectraPure

®

SpectraPure

®

Inc.

480.894.5437 Call us toll-free 1.800.685.2783

2167 East Fifth St, Tempe, Arizona 85281

5

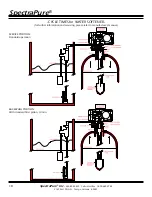

Lubricate surface

lightly on both

connections

METAL CLIP

W/ SCREW

BACKWASH

TO DRAIN

INTERNAL LOCK CONNECTION

FOR COLLECTOR SCREEN

THREADING

TO TANK

Insert this side into lock

connection on Control

Head.

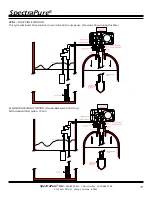

NOTE: Install the Carbon Tank with the

inlet, outlet and drain connections that

meet applicable plumbing codes.

Perform all plumbing according to local plumbing codes.

— Use a 1/2" minimum pipe size for the drain.

— Use a 3/4" drain line for backwash flow rates that

exceed 7 gpm or length that exceeds 20’ (6 m).

Plumbing components (as shown in picture) such as

copper piping, braided tubing and fitting do not come

with the water softener. They are readily available at

any hardware store or your local plumber.

FRONT VIEW FOR CONTROL HEAD

BACK VIEW FOR CONTROL HEAD

COLLECTOR SCREEN