10

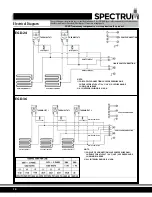

NOTE:

1) FOR SUPPLY CONNECTIONS USE COPPER WIRE ONLY,

SUITABLE FOR AT LEAST 194°F (90°C). USE WIRE GAUGE

SHOWN OR LARGER

2) ALL INTERNAL WIRING IS #14 GA

SINGLE PHASE CONNECTION

3 PHASE CONNECTION

THERMOSTAT 2

THERMOSTAT 1

PILOT LIGHT 1

PILOT LIGHT 2

ON/OFF SWITCH 1

ON/OFF SWITCH 1

3 PHASE CONNECTION

SINGLE PHASE CONNECTION

ON/OFF SWITCH 2

ON/OFF SWITCH 3

ON/OFF SWITCH 2

HEATING ELEMENTS 1

HEATING ELEMENTS 2

THERMOSTAT 2

THERMOSTAT 3

THERMOSTAT 1

PILOT LIGHT 2

PILOT LIGHT 3

PILOT LIGHT 1

HEATING ELEMENTS 1

HEATING ELEMENTS 2

HEATING ELEMENTS 3

NOTE:

1) FOR SUPPLY CONNECTIONS USE COPPER WIRE ONLY,

SUITABLE FOR AT LEAST 194°F (90°C). USE WIRE GAUGE

SHOWN OR LARGER

2) ALL INTERNAL WIRING IS #14 GA

Electrical Diagram

The circuit diagrams are provided to assist qualified technicians. Only SPECTRUM agents or Recommended Qualified Technicians

should carry out repairs if needed. (Refer to page 11 for service arrangements)

DO NOT remove any components or service panels on this product.

EGD-24

EGD-36

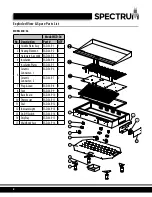

Summary of Contents for EGD-24

Page 12: ......