7 |

P a g e

7

DESCRIPTION & OPERATION

SECTION 1 Instruction Manual

DESCRIPTION OF OPERATION

Optical Loop Interface Unit

This unit consists of a box assembly with 2 optical sensors (fitted in the centre of the top cover), which

operate in conjunction with a opto sensing board inside the unit. The optical sensors detect the presence

of the paper loop between the outfeeding printer or unwinder and the infeeding forms cutter and

maintains it at a height set by the operator. It has a maximum height detection range of 300 mm, which

can be adjusted internally.

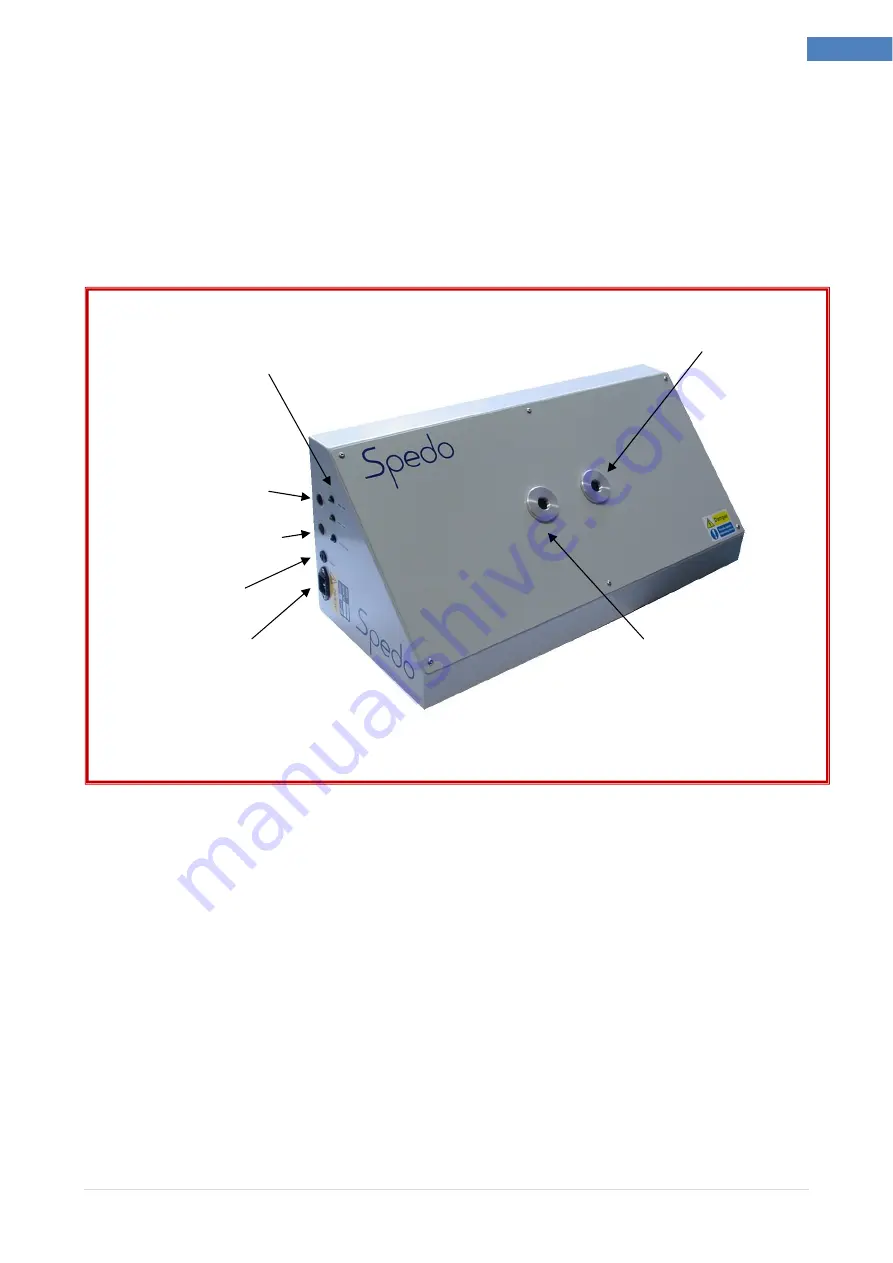

Fig 1.2 Identification of Main Parts

Operation with Ancillary Units

Optical Loop Interface Unit is supplied with mains power from the forms cutter by interconnecting it with

the mains lead supplied. The sync lead is also connected to the forms cutter. Several cables are provided

for interfacing with input devices and care must be taken to ensure the correct cable is used.

Both sensor have been factory set for optimum running conditions (300mm for the cutter control sensor

and 100mm for the printer control sensor) but these can be adjusted if necessary.(see page 9)

Printer Control Sensor

Cutter Control Sensor

Printer Interface Output

Mains Power Input

Fuse 800mA

Cutter Interface Output

Status Indicators