Page 10

CONNECTION TO TRACTOR

IMPORTANT:

The tractor must be able to handle Category I or Category II three-point hitch implements and be

equipped with a four-way valve (for double-acting cylinders) and hydraulic outlets.

NOTE:

For closed center tractor hydraulics, please install Closed Center spool conversion kit 582328 provided with splitter.

1) The tractor owner’s manual should be consulted for instructions on tractor operation, safety and auxiliary hydraulic

systems pressure and return flow hookups.

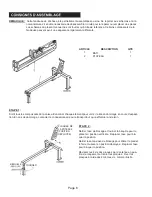

2) Back the tractor into position and slide the lift arms over the draw pins on the frame assembly(18). Secure with lynch

pins (not provided). Attach the top link from the tractor to the clevis on the A-frame/stand and secure with a top link pin

and a lynch pin.

3) Locate the pressure and return ports on the rear of the tractor.

4) Connect the hoses from the tractor to the log splitter with the flow from the pressure port entering on the “IN” side of

the valve. The return flow to the tractor should attach to the “OUT” side.

5) After connecting the hoses, activate the auxiliary valve to provide hydraulic power to the splitter. If the tractor engine

pulls down or if the hydraulic oil is heard going over relief, return lever to neutral and check all hoses, fittings, and con

-

nections. If hydraulic system is operating normally, secure tractor auxiliary valve into on position. Check if the wedge

moves in the same direction as the lever is moved. If reversed, the flow must be switched by swapping the hoses to the

splitter or by reversing the auxiliary valve on the tractor. If the splitter is used with the flow reversed, the relief valve in

the splitter valve does not work and could result in damage to the tractor or the log splitter.

6) The tractor hydraulic system should be capable of delivering 6 to 20 GPM of oil at 1500 to 2500 PSI for adequate

splitting force and speed. The tractor should have a hydraulic oil cooling system to allow semi-continuous operation.

NOTE: Hoses to the tractor are not included.

Specifications of the hoses and fittings supplied by the owner should

be within recommended ranges of the tractor operating pressure.

7) Using the tractor three-point hitch, raise the log splitter to a convenient height and level with the top link. The log

splitter may be operated in either the horizontal and vertical position. See illustration on page 3.

8) To deploy rear stand:

a) At rear work extension stand, remove pivot lock pin and pivot stand down to the vertical position. Reinstall pivot

lock pin.

b) Remove extension lock pin and slide lower leg of stand down until it touches the ground. Reinstall lock pin in one

of the three holes that best lines up with inner stand hole.

9) For converting open center valves to closed center: Instructions are included in the kit. Closed spool kit 582328 is

included with splitter.

OPERATION

WARNING:

See safety information related to operation of the log splitter on page 5 of this manual. Make

sure that you have the recommended personal protective equipment described on page 5.

1) Setup tractor in a clear level area. Set the tractor parking brake and lower splitter to the ground.

2) Adjust top link to level the beam and lower and adjust rear stand to provide additional stability. The splitter must

always remain securely attached to the tractor’s three point hitch while in use.

WARNING: Read and thoroughly understand all instructions in this manual and on safety decals

before assembling or operating this log splitter. Failure to do so may cause serious injury or

death. Do not allow anyone to operate this log splitter who has not read this manual. As with all

power equipment, a log splitter can be dangerous if assembled or used improperly. Do not

operate this log splitter if you have any questions concerning safe operation. To get answers to

any questions, call our technical support department at 1-800-525-8322.