ASSEMBLY INSTRUCTIONS

NOTE:

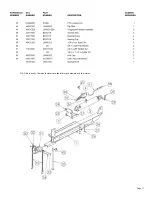

This log splitter was partially assembled at the factory. Refer to the drawing and parts list should it become necessary to disassemble the

unit for repair or replacement of parts.

STEP 1:

Remove all the components from the crate. Inspect each piece for shipping damage. If any part is damaged, contact your dealer or

delivering carrier.

NOTE: Refer to the exploded view drawing on pages 11 and 12 when assembling this log splitter

STEP 2:

Remove the tank/engine assembly (2) from the crate and set it on the ground. Make sure that it is stable.

STEP 3:

Remove the rubber covering from the two spindles on the tank/axle (2). The wheel bearing cups, bearing cones, grease seals and hub

caps are already assembled. Bearing cones have been greased at the factory. Remove the hub cap (53) by prying it loose with a

common tip screwdriver. Mount the wheels (45) to the spindles on the tank/axle (2) using the 3/4 in. light flatwasher (50) and 3/4 in.

slotted nut (51) from the hardware kit.Tighten the nut until bearing play is removed and the wheel will still rotate freely. Install the cotter

pin (52) and hub cap (53). Repeat step 4 for the other wheel.

STEP 4:

Check to make sure that the tank/axle assembly (2) is stable and will not roll. Blocking the wheels will help to prevent any movement. Position the

beam assembly (1) over the plate with the four holes on the tank/engine assembly (2). When the holes are aligned, insert the four 1/2 in. UNC x

1 in. GR 5 bolts (26), the four 1/2 in. lock washers (25) and the four 1/2 in. UNC nuts (24). Tighten the nuts and bolts.

STEP 5:

Connect the 3/4 in. x 7-1/2 in. return hose (22) to the 3/4 in. 45° fitting on the valve (4). Secure with a hose clamp (19). Tighten clamp.

STEP 6:

Connect the 1/2 in. x 21 in. pressure hose (21) to the swivel fitting (40) on the valve (4). Tighten.

OPERATING INSTRUCTIONS

STEP 1: STARTING

WARNING: Read and thoroughly understand all instructions and safety information before operating

this log splitter. Failure to do so may cause serious injury or death. Do not allow anyone to operate this

log splitter who has not read this manual. As with all power equipment, a log splitter can be dangerous

if assembled or used improperly. Do not operate this log splitter if you have doubts or questions

concerning safe operation. Call our customer service department at 1-800-525-8322 to address these

concerns.

Si no entiende ingles, se prefiere que busque alguien que interprete las instrucciones para usted.

IMPORTANT:

The engine and hydraulic tank are shipped without oil. See the engine operating and maintenance instructions manual packed

with the log splitter for the type of crankcase oil, fuel, etc. The engine manufacturer recommends lead-free gasoline only.

Please note that this log splitter is available with either a SpeeCo 6.5 HP or a Honda GC 190 engine. Please follow the appropriate

instructions for your engine.

CAUTION:

DO NOT START OR RUN THE ENGINE WITHOUT OIL IN THE HYDRAULIC RESERVOIR AND IN

THE ENGINE.

Page 7

STEP 2:

The hydraulic reservoir should be filled with an AW46 hydraulic oil. If hydraulic oil is difficult to obtain, automatic transmission fluid can

be substituted and should be used instead of hydraulic oil when temperatures are below 32 degrees. Use only clean oil and take care to

prevent dirt from entering the hydraulic reservoir.

CAUTION:

WHEN TIGHTENING THE BREATHER CAP ON THE TANK, POINT THE HOLE AWAY FROM THE ENGINE

AND THE OPERATOR ZONE.