Model No. ____________________

Serial No. _____________________________

Date of Purchase _______________

Place of Purchase _______________________

_______________________

_______________________

_______________________

IMPORTANT NOTICE

We, the manufacturer, reserve the right to change the product and/or specifications in this manual without notification.

The manual is for information usage only and the pictures and drawings depicted herein are for reference only.

Page 14

Warranty Repair and Service

Do not return this product to the store for warranty issues or repair. Call 1-800-525-8322 for the location of the

nearest service center.

Record the information below for future reference.

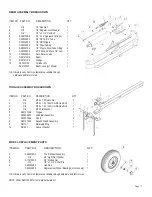

Location: Tank/tongue plate

below beam

Serial Number Label

NOTES