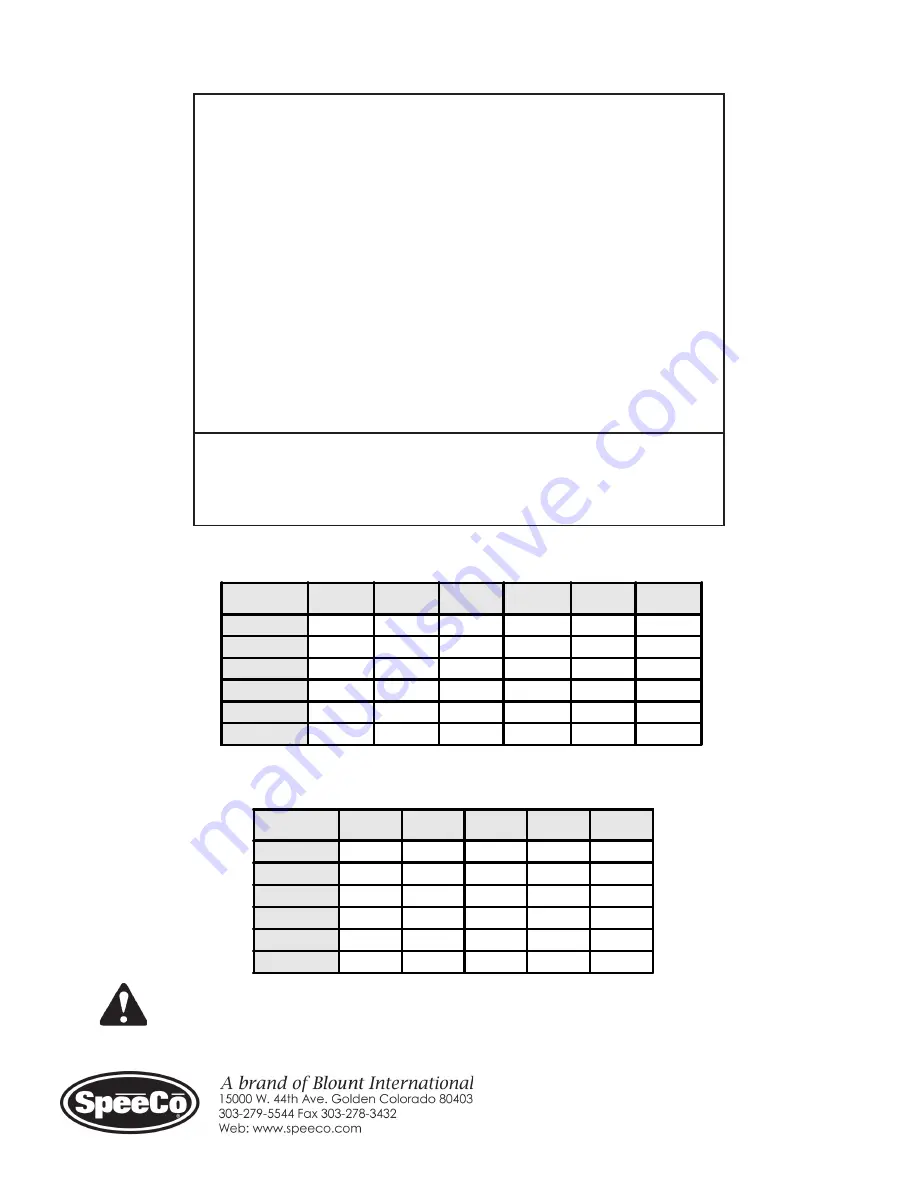

Splitting Force (tons)

Cylinder Size

1000 PSI 1500 PSI 2000 PSI 2500 PSI 3000 PSI 3500 PSI

3"

3.5

5.3

7.1

8.8

10.6

12.4

3-1/2"

4.8

7.2

9.6

12.0

14.4

16.8

4"

6.3

9.4

12.6

15.7

18.8

22.0

4-1/4"

7.1

10.6

14.2

17.7

21.3

24.8

4-1/2"

7.9

11.9

15.9

19.9

23.9

27.8

5"

9.8

14.7

19.6

24.5

29.5

34.3

Cylinder Size

5 GPM

10 GPM

15 GPM

20 GPM

25 GPM

3" x 24"

15.4

7.7

5.1

3.9

3.1

3-1/2" x 24"

21.8

10.9

7.3

5.4

4.4

4" x 24"

28.3

14.2

9.4

7.1

5.7

4-1/4" x 24"

32.4

16.2

10.8

8.1

6.5

4-1/2" x 24"

36.6

18.3

12.2

9.2

7.3

5" x 24"

45.0

22.5

15.0

11.3

9.0

Cycle Time (seconds)

CAUTION: This log splitter is designed for tractors with pressure ratings under 3200 psi.

Warranty will be voided if used on tractors that exceed pressure settings of 3200 psi.

Do not exceed the pressure rating of the cylinder and valve manufacturers

Tractor Categories

1 and 2

Maximum Splitting Force

Depends on tractor*

Cycle Time

Depends on tractor*

Maximum Log Length

26”

Cylinder

4” diameter x 24” stroke

Valve

Auto-return

Beam Size

6” x 9”

Wedge

7” high with spreader wings

Hitch

Tractor 3-point

Height

42” horizontal

72” vertical

Width

22”

Length

72”

Shipping Weight

365 lbs.

*Splitting force is determined by cylinder size and tractor PSI. Cycle time depends on

cylinder size and GPM’s that the tractor produces. Tractor should ideally produce 8-15

GPM at 1500 to 2500 PSI Do not exceed 3200 PSI. See tables below for approximate

splitting force and cycle time.

SPECIFICATIONS

Part No.S53010600