13

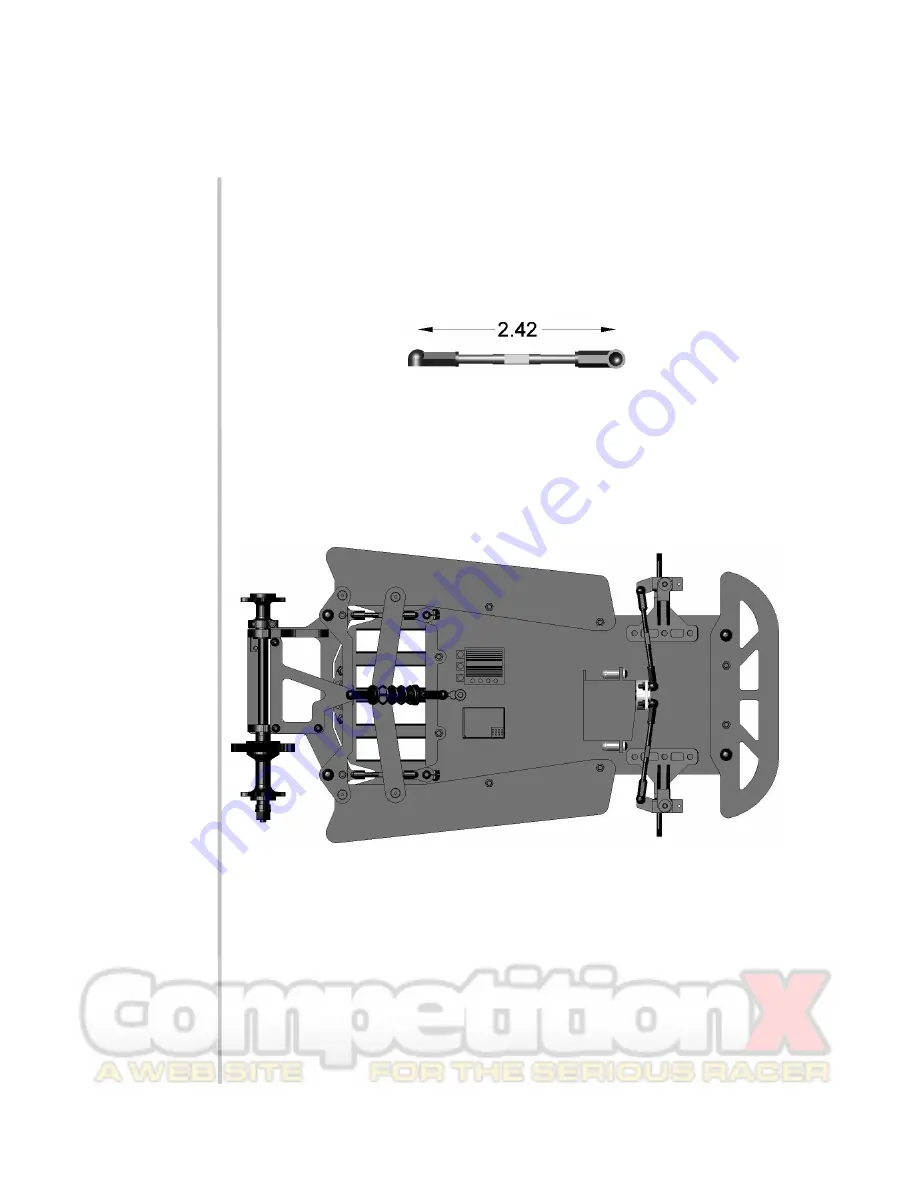

Using the remaining plastic ball cups (x2)(smr1423) and 4-40 turnbuckles

(x2)(smr1297), assemble them into the steering linkage as shown below,

paying attention to keeping the turnbuckle equally threaded into the ball cups.

This will allow adjustment without the danger of bottoming the turnbuckle

inside the ball cup. The dimension shown is to get the length roughly the

correct length. Shown is the left hand turnbuckle, the right hand will have the

ball cup on the right facing away from you. Fine tuning of the linkage will have

to be completed when it is assembled on the model.

After installing the linkage onto the chassis, it should appear as shown below.

The remaining hardware is for mounting the front wheels: 1/8” x 5/16” flanged

bearings (x4)(smr5003) to be mounted into the front tires of your choice, 4-40

mini lock-nuts (x2)(smr2080) used to secure the front wheels to the front axles.

Tip: be sure when tightening the front wheel nuts not to crush the bearings.

The nuts should just touch the inner bearing race with the wheel seated flush

against the steering block. To test for over tightened nuts, spin the wheel while

tightening the wheel nut. When the nut causes the wheel to slow, back the nut

off until there isn't any more compression and the wheel spins freely.

More remaining hardware is as follows: 4-40x 1/2” socket head cap

screws (x8)(smr2024). These are used for mounting the rear tires of your

choice. Tighten these till the screws are firmly secured. Over tightening

will cause the rims to deform and not run true. It could also lead to

premature rim failure.

Installing the electronics using the layout shown has proven to be the

most efficient layout. This allows the positive wires to go to the battery on

the left side, then straight back to the motor (non-reversing ESC). The

negative battery lead to the right, while the motor negative goes straight

back. Tip: route the motor wires down the centerline of the car, following

the shock. This will keep from imposing tweak between the motor pod

and main chassis.