2

Chassis prep:

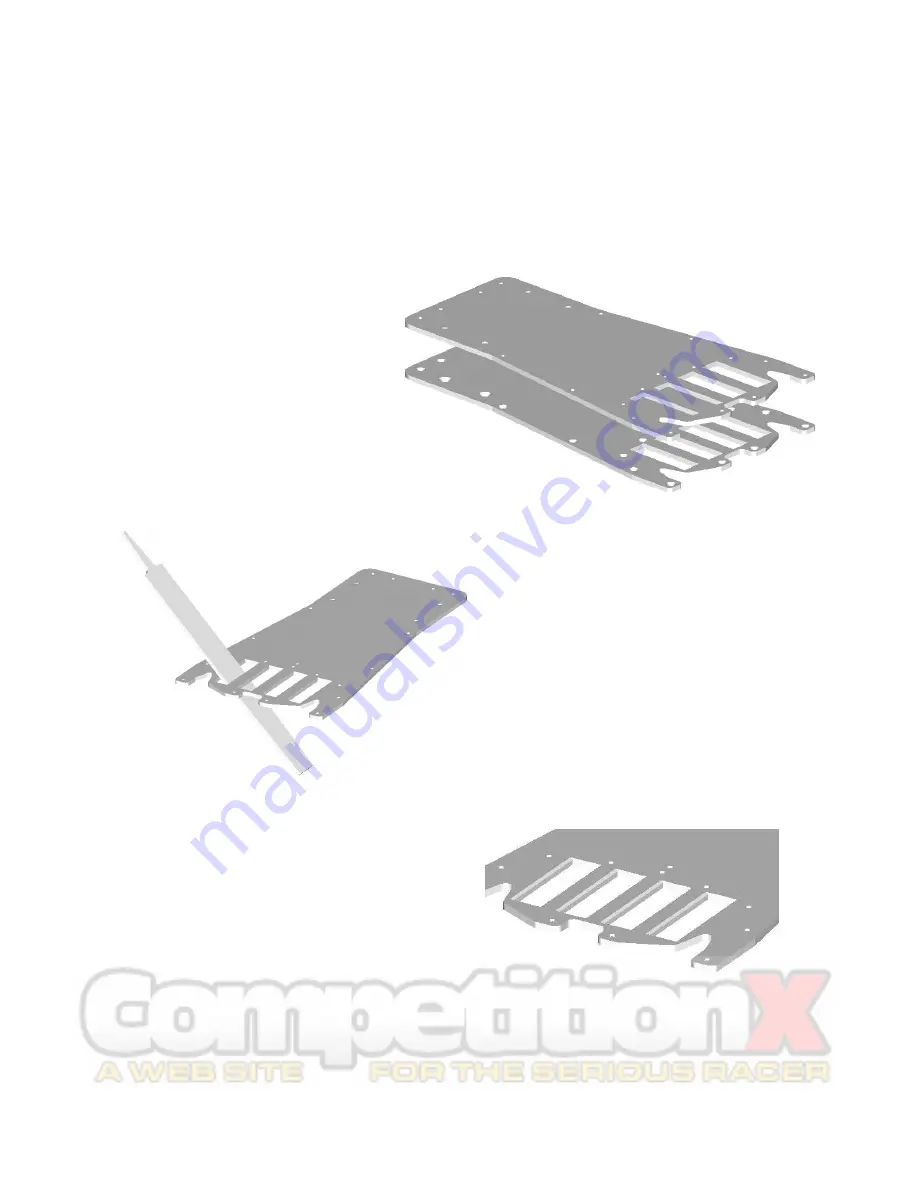

Shown here is the chassis top and

chassis bottom. Note that the chassis

bottom has countersunk holes. To

prep this chassis you will need to file

the battery slots to keep from cutting

the insulation labels on the batteries.

This will also allow the battery pack to

sit lower in the chassis, lowering the

center of gravity.

top

bottom

When filing the slots, file from the top

side of the chassis with the file at a 45°

angle. Have an assembled 4-cell battery

pack handy to check depth as the

chassis is filed. Removing too much

material will allow the battery pack to sit

too low and could rub on the ground in

high speed corners.

After filing, the slots should look something like

the illustration to the right. If you filed the slots

too low and the battery sits lower than the

bottom of the chassis, they can be built back up

slowly using multiple layers of thick

cyanoacrylate (CA) glue.