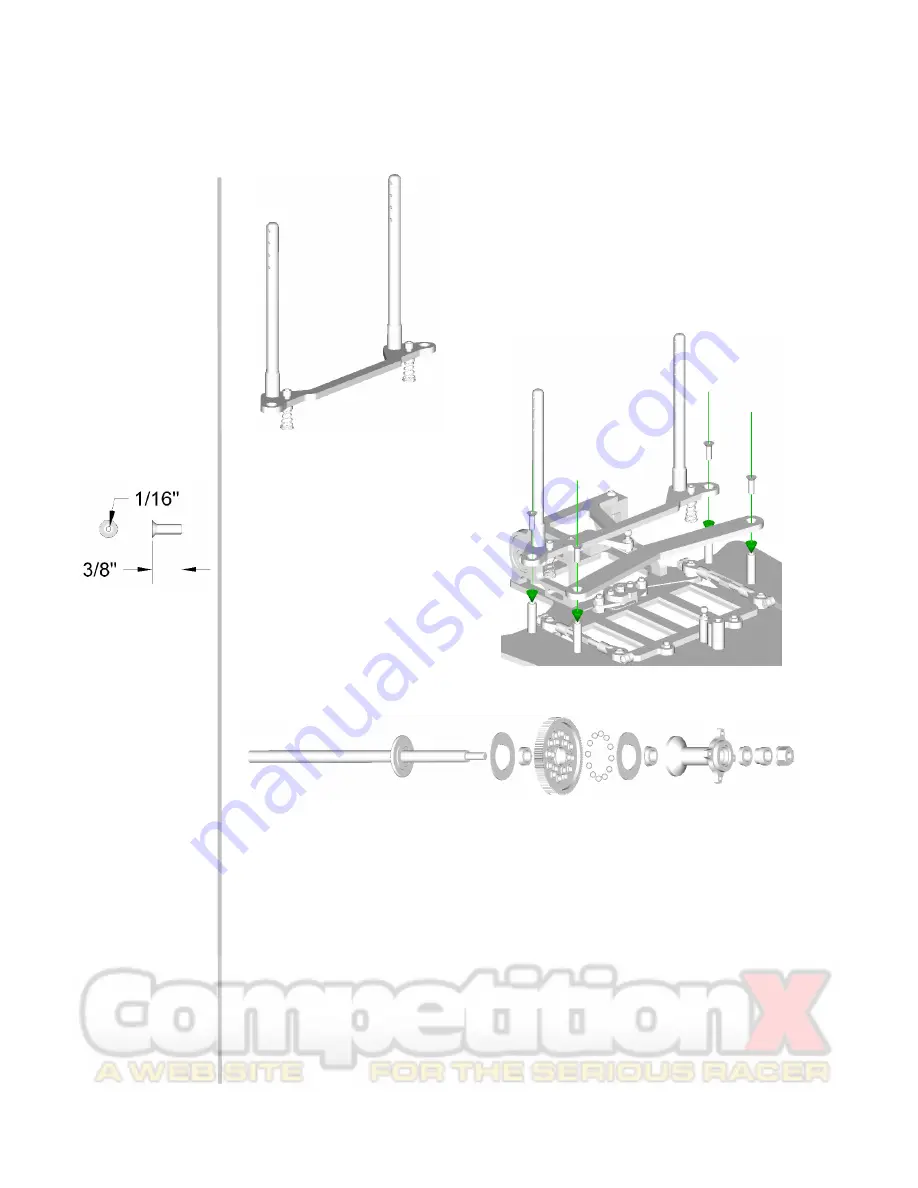

Install the tweak springs, only after the CA glue has

fully cured, by pushing and twisting the spring in a

clock-wise motion until it ‘clicks’ into position.

Assemble the tweak plate to the

chassis using 4-40 x 3/8” flat head

screws (smr2012)(x2) and a little

drop of blue thread lock.

Next locate the battery hold down

plate and install with 4-40 x 3/8”

flat head screws (smr2012)(x2).

Note: no thread lock here!

Find the parts bag containing the rear axle and differential (diff) parts.

From left to right shown above is; the rear axle, diff ring, 3/8” x ¼” un-flanged

bearing, 100 tooth spur gear, 1/8” diff balls (x12), diff ring, 3/8” x ¼” flanged

bearing, right hub, 3/8” x ¼” flanged bearing, thrust cone, nylon diff nut.

These components will be installed in that order. Silicone diff grease should be

used on the balls after installation into the spur gear (both sides).

Tip: to aid in the assembly, put 3 to 4 dots of grease on the axle flange, and on

the right hub before mounting the diff rings. This will hold the rings in place until

the assembly is completed.

When tightening the diff nut, tighten it down slowly until it just starts to tighten the

diff. From this point on, only tighten ¼ turn increments, spinning the axle while

holding the spur from turning. This will allow the diff to break in slowly. Keep

tightening the diff nut until it’s difficult to spin the spur while holding the axle and

right hub firmly.

4-40 x 3/8”

flat head