E

N

G

L

I

S

H

Speedaire Operating Instructions & Parts Manual

15D802

7

Speedaire

Gasoline Air

Compressor, Generator

and Welder

®

3. Move the GEN/WELD switch to the

GEN position.

NOTE: Failure to allow the engine to cool

at idle for two (2) minutes may result in

damage to the generator.

4. Drain air from the air tanks by

releasing air with an attached air

tool or by pulling on the Safety

Relief Valve.

5. Once the Air Tank Pressure Gauge

registers under 10 pounds, open

the drain valve under each air tank

to drain any moisture.

6. Close fuel valve on unit or engine.

7. Allow the unit to cool down.

8. Wipe the unit clean and store in a

safe, non-freezing, dry area.

OPERATING CONTROLS

Idle Control Operation:

Note: Idle control is disabled in welding

mode. Idle control switch must be at full

throttle setting.

The idle control is factory installed.

This electrical device is designed to let

the engine run at fuel saving low idle

speed when the generator or compres-

sor are not loaded, and at full normal

governed speed when a load is applied.

The idle system overrides the engine

governor to provide idle speed. When

a load is applied, the electronic circuit

reacts to de-energize the idle system

so that the engine can resume full gov-

erned operating speed.

The idle control system controls the

engine speed in the following manner:

1. With the idle control switch in the

“FULL THROTTLE” position, start

the engine.

2. After one or two minute warm up

period, apply load and move the

switch to the “IDLE CONTROL”

position. The engine will throttle

back to idle speed following a 5-8

second delay.

3. When a load is applied to the

generator or air compressor tank

pressure drops below regulated

set point, the idle control system

becomes de-energized. The engine

then accelerates to normal op-

erating speed, controlled by the

governor.

4. When the load is removed or

air compressor tank pressure is

restored, the idle system becomes

re-energized and throttles the en-

gine back to idle speed after a 5-8

second delay.

NOTE: While the engine is idling, the

generator voltage is automatically

reduced to reduce generator

temperatures. The voltage will return

to normal levels immediately upon the

application of load.

MAINTENANCE

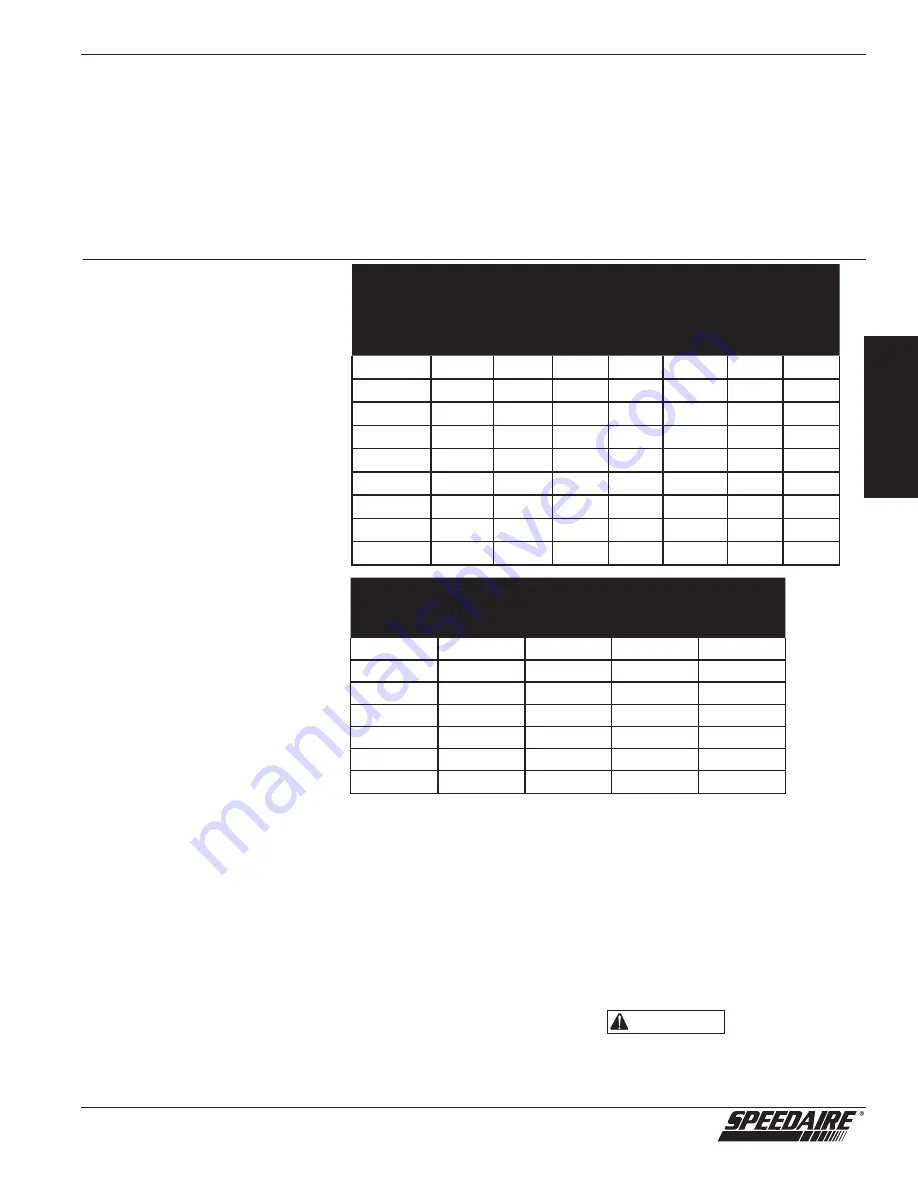

Cable Size:

Equipment damage can result from low

voltage. Therefore, to prevent excessive

voltage drop between the unit and the

equipment, the cable should be of ad-

equate gauge for the length used. The

cable selection chart gives the maxi-

mum cable lengths for various gauges

of wire which can adequately carry the

loads shown.

Electric Motor Loads:

It is characteristic of common electric

motors in normal operation to draw up

to six times their running current while

starting. This table may be used to esti-

mate the watts required to start “CODE

G” electric motors.

If an electric motor fails to start or

reach running speed, turn off the

appliance or tool immediately to

CURRENT

LOAD IN

WATTS

MAXIMUM CABLE LENGTH (FEET)

IN AMPS

120

VOLTS

240

VOLTS

#8

WIRE

#10

WIRE

#12

WIRE

#14

WIRE

#16

WIRE

2.5

300

600

1000

600

375

250

5

600

1200

500

300

200

125

7.5

900

1800

350

200

125

100

10

1200

2400

250

150

100

50

15

1800

3600

150

100

65

20

2400

4800

175

125

75

50

25

3000

6000

150

100

60

30

3600

7200

125

65

40

4800

9600

90

CAUTION

WATTS REQUIRED TO START MOTOR

MOTOR

(H.P.)

RUNNING

WATTS

REPULSION

INDUCTION

CAPACITOR

SPLIT

PHASE

1/8

275

600

850

1200

1/6

275

600

850

2050

1/4

400

850

1050

2400

1/3

450

975

1350

2700

1/2

600

1300

1800

3600

3/4

850

1900

2600

1

1100

2500

3300