14

MAINTENANCE /

REP

AIR

TROUBLESHOOTING

OPERA

TION

ASSEMBL

Y /

INST

ALLA

TION

SAFETY

/

SPECIFICA

TIONS

GETTING ST

ARTED

Start-up Information (Continued)

4. Check direction of rotation by quickly bumping the power to ON and having someone else watch the motor

pulley to see which way it turns. Belt guard should remain installed. Also check the direction of rotation of the

oil cooler fan. The fan must suck air in from the wire guard side and push air out through the radiator when

turning the correct direction. This can be checked by holding a small strip of paper in front of the radiator.

With the correct direction of rotation the paper will blow out away from the radiator.

5. Turn on the incoming power at the disconnect switch/circuit breaker. The motor will not turn on with this step.

6. Push the on/off button.

7. Keep your hand on the on/off button, ready to turn off immediately after start up to check the rotation

direction. Also check the direction of the cooler fan.

Note: Turn unit off immediately if the rotation of the pump or fan are running the wrong direction.

8. Immediately turn off the on/off switch. The motor will stop with this step.

9. If the direction of rotation is incorrect, disconnect, lock out and tag out all incoming power. Change the

position of two of the incoming power lines and repeat steps 5-10.

10. When the direction of rotation has been confirmed the compressor is ready to run for an initial start up

operation check.

OPERATING INSTRUCTIONS

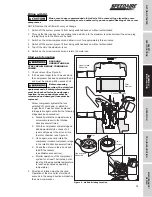

Oil Level Check (See Figure 8)

• Check oil level by removing oil plug.

• With hot oil, the level will be higher than with cold oil.

As a result, oil may escape when the oil plug is opened at the maximum oil level. If this does happen, close the

oil plug immediately and carefully clean up the oil that has escaped.

NOTE: The oil plug is provided with a safety hole on the side from which oil or air escapes if there is any residual

pressure in the air end. Wait for one minute after the unit is at standstill before opening the oil plug.

1. Switch off the system, prevent it from being switched back on without authorization.

2. Wait for one minute at standstill.

3. Unscrew the oil plug on the filler neck by hand with the air end depressurized.

4. Check the oil level.

5. If necessary, top off oil of the same oil type and the same brand up to the maximum level (see Figure 8 and

Lubrication section).

NOTE: The oil filler neck is positioned so that it is not possible to overfill the system. Excess oil runs out of the

filler neck.

6. Screw on the oil plug firmly by hand.

7. Switch on the system.

8. Wipe off and clean up any spilled oil.