E

N

G

L

I

S

H

E

S

P

A

Ñ

O

L

F

R

A

N

Ç

A

I

S

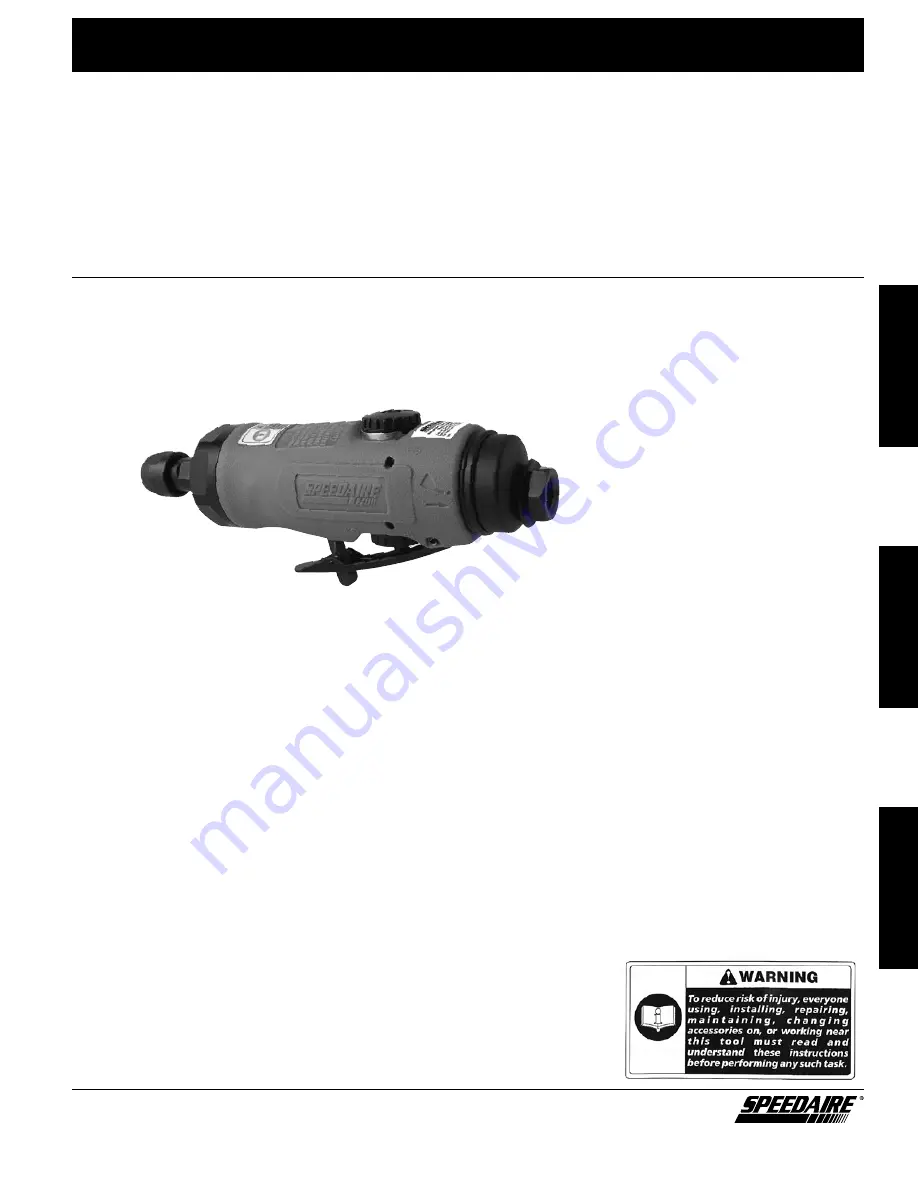

Speedaire

®

Reversible

Die Grinder

Operating Instructions & Parts Manual

5YAR8

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

Form 5S623

Printed in Taiwan

04634

Version 0

KKU372

08/10

#626

Description

Speedaire® general duty straight die grinder is designed for cleaning tire molding, porting

and general high-speed polishing and grinding. Features energy efficient 1/2 hp motor,

1/4" collet, safety throttle and rear exhaust.

Includes:

1 - Die Grinder

2 - Wrenches

Figure 1

Unpacking

When unpacking the unit, carefully look for

any damage that may have occurred during

transit. Check for loose, missing or damaged

parts.

Specifications

Free Speed ....................................18, 000 RPM

HP ................................................................. 0.7

Exhaust ......................................................Rear

Length ..................................................... 7-1/2"

Collet Size .................................................. 1/4"

Average Air Consumption

@ 15 Second Run Time ...................... 3.35 CFM

Minimum Hose Size ............................3/8" I.D.

Air Inlet ...............................................1/4" NPT

Maximum air pressure ............................90 PSI

Weight ...................................................1.6 lbs.

General Safety Information

1.

For Additional Safety

Information Consult:

Your employer, union, and/or trade

association. US Department of Labor

(OSHA); www.osha.gov. “Safety Code

For Portable Air Tools” (B186.1)

2.

Entanglement Hazards

Keep away from rotating drive.

Do not wear jewelry or loose

clothing.

Choking can occur if neckwear

is not kept away from the tool and

accessories.

Scalping can occur if hair is not kept

away from the tool and accessories.

Avoid direct contact with accessories

during use.

Use only proper accessories designed

for use with pneumatic screwdrivers,

nutrunners, ratchets and pulse tools. 2.

3.

Projectile Hazards

Always wear impact-resistant eye

protection when involved with or

near the operation, repair or

maintenance of the tool or changing

accessories on the tool.

Be sure all others in the area are wearing

impact-resistant eye protection.

Even small projectiles can cause eye

injuries and blindness.

4.

Workplace Hazards

Slip/Trip/Fall is a major cause of serious

injury or death. Beware of excess hose

left on the walking or work surface. High

sound levels can cause permanent hearing

loss. Use hearing protection as

recommended by your employer or OSHA

regulation (see 29 CFR part 1910).

Maintain a balanced body position and

secure footing. Repetitive work motions,

awkward positions and exposure to

vibration can be harmful to hands and

arms. If numbness, tingling, pain or

whitening of the skin occurs, stop using

tool and consult a physician. Avoid

inhaling dust or handling debris from the

work process which can be harmful to

your health. Use dust extraction and wear

respiratory protective equipment when

working with materials which produce

airborne particles. This tool is not

intended for use in explosive atmospheres

and is not insulated for contact with

electric power sources.Potentially

explosive atmospheres can be caused by

dust and fumes resulting from sanding or

grinding.

Use dust extraction or suppression system

which is suitable for the material being

processed.

Some dust created by power sanding,

sawing, grinding, drilling and other

construction activities contains chemicals

known to the State of California to

cause cancer and birth defects or other

reproductive harm.

Some examples of these chemicals

are:

– Lead from lead based paints

– Crystalline silica bricks

and cement and other masonry

products

– And Arsenic and chromium

from chemically-treated rubber

Your risk from these exposures

varies, depending on how often

you do this type of work. To reduce

your exposure to these chemicals:

work in a well ventilated area, and