2

E

N

G

L

I

S

H

Speedaire

®

Reversible Die Grinder

5YAR8

Speedaire® Operating Instructions and Parts Manual

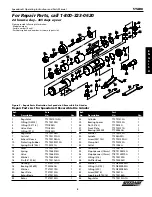

Figure 2 - Air Diagram

work with approved safety

equipment, such as dust masks that

are specially designed to filter out

microscopic particle

5.

Air Supply and Connection

Hazards.

Air under pressure can cause severe

injury.

Always shut off air supply, purge hose of

air pressure and disconnect tool from air

supply when not in use, before changing

accessories or when making repairs.

Never direct air at yourself or others.

Whipping hoses can cause serious injury.

Always check for damaged or loose hoses

and fittings.

Do not use quick disconnect

couplings at tool. For correct set up see

Figure 2 for correct set up.

When universal twist couplings

are used, lock pins must be installed.

Do not exceed maximum air pressure of

90 PSI or as stated on tool nameplate

.

Installation

Designed to operate on 90 PSI, lower

pressure (below 90 PSI) will reduce

performance of the tool while higher air

pressure over 90 PSI raise the performance of

the tool beyond its rated capacity and could

cause serious damage to tool and user.

Always use clean dry air. Excessive moisture

and dirt will greatly reduce the life of any air

motor. We recommend the installation of an

in-line filter-regulator-lubricator as close to

the tool as possible.

Pre-Operation

Before the tool is connected to the air

supply, clean the air hose of accumulated

dust and moisture. Before removing a tool

for service or changing accessories, make

sure the air line is shut off and drained of air.

This will prevent the tool from operating if

the throttle is accidentally engaged.

Operation

1. Supply tool with 90 PSI of clean, dry air.

Higher pressure drastically reduces tool

life. Connect tool to air line using pipe,

hose, and fitting sizes shown in Figure 2.

Do not install a quick coupler directly into

the grinder throttle handle.

2.

Operating Hazards

Never mount a grinding wheel, cut off

wheel or router cutter on a die grinder

or tire buffer. A grinding wheel or other

accessory that bursts can cause very

serious injury or death.

Grinding accessory's rated speed must be

equal to or greater than the speed of the

die grinder.

Use only mounted wheels or tire buffing

accessories with adequate speed rating

and the correct shaft diameter.

Do not use wire brushes, drill bits, or any

other accessory other than mounted

wheels, burrs and tire buffing accessories.

Damaged, warn or incorrectly mounted

accessories can cause higher vibration.

To reduce exposures to vibration ensure

burring tools are sharp and this tool

and all accessories are in proper working

condition.

Ensure that the workpiece is properly

supported.

Avoid direct contact with rotating spindle

and accessory to prevent cutting of hands

or other body parts. Wear gloves to help

protect hands. Tool continues to run after

the throttle lever has been released.

Do not disable the lock off feature on the

throttle lever.

This tool and its accessories must not be

modified.

Operators and maintenance personnel

must be physically able to handle the

power of the tool and capable of

performing the job task.

Always wear impact-resistant eye and face

protection when involved with or near

the operation, repair or maintenance of

the tool or changing accessories on the

tool.

Gloves and protective clothing are

recommended.

Even small projectiles can cause eye

injuries and blindness.

Be sure all others in the area are wearing

impact-resistant eye and face protection.

Measure the air tool speed daily with a

tachometer to make sure it is not greater

than the RPM marked on the grinding

accessory.

Maximize the gripping length of the

accessory, it must not be less than .390 in.

(10mm). Increased overhang of a

mounted wheel reduces its permitted

speed - Refer to manufacturer's

recommendations and (ANSI B7.1).

3.

Air Supply and Connection

Hazards.

Air under pressure can cause severe

injury.

Always shut off air supply, drain hose of

air pressure and disconnect tool from air

supply when not in use, before changing

accessories or when making repairs.

Never direct air at yourself or

anyone else.

Whipping hoses can cause serious injury.

Always check for damaged or loose hoses

and fittings.

Do not use quick disconnect couplings at

tool. See Figure 2 for correct set up.

Whenever universal twist couplings

are used, lock pins must be installed.

Do not exceed maximum air pressure of

90 PSI or as stated on tool nameplate

.

Maintenance

Lubrication

Use an air line lubricator with Mobil Almo

525 air tool oil (model 4ZF22), adjusted

to two (2) drops per minute. If an air line

lubricator cannot be used, add air motor

oil to the inlet once a day.