To avoid injury to hands and fingers:

• Always wear heavy leather gloves when handling a wire rope.

• Never let wire rope slip through your hands.

• Always be aware of possible hot surface at winch motor, drum or wire rope during or

after winch use.

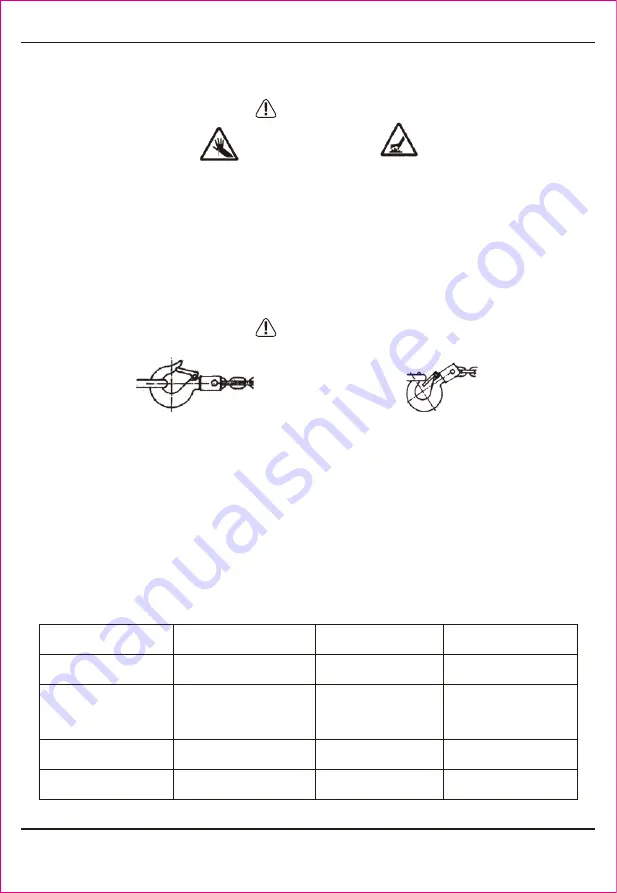

Moving Parts Entanglement Hazard

Failure to observe these instructions could lead to minor to moderate injury.

• Never apply load to hook tip or latch. Apply load only to the center of hook.

• Never use a hook whose throat opening has increased, or whose tip is bent or twisted.

CUT AND BURN HAZARD

MOVING PARTS ENTANGLEMENT HAZARD

GENERAL SAFETY PRECAUTIONS

feedback@natitools.com

3

1-800-348-5004

CAUTION

CAUTION

WINCH SPECIFICATIONS DATAS:

Pulling Capacity

Gears

Cable (Dia.xl)

Braking

Control

3,000 lbs (1363kgs)

Split Ring

3/16” x 43ft.

Automatic Inside

Wired

Wireless (Optional)

Motor (12V)

Gear Ratio

Drum (Dia.xl)

Mounting Pattern

Clutch

1.5HP Series Wound

153:1

1-1/4” x 2-7/8”

3” Dia. x 4-7/8”

Sliding Ring Gear