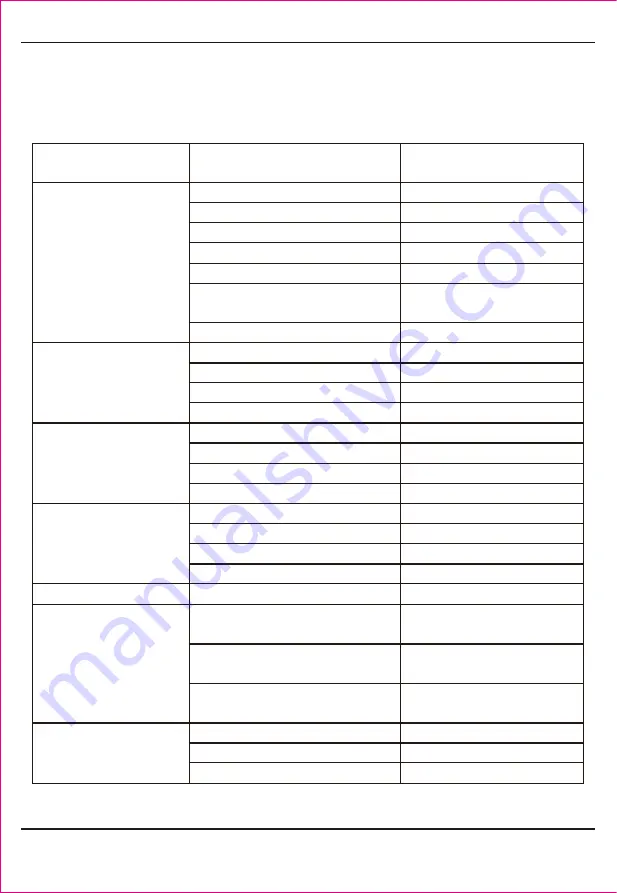

When the winch fails to operate after several attempts, or if there is any fault operation while

winching, check followings.

TROUBLE SHOOTING

feedback@natitools.com

8

1-800-348-5004

Winch will not operate

Cut circuit or loosing

Weak battery or insufficient power

Damaged over load protector

Loose connection of wirings

Damaged or stuck solenoid

Defective remote control

Damaged motor or worn carbon brush

Broken wiring or bad connection

Damaged or stuck solenoid

Switch inoperative

Dropt or lost wiring

Freespool not disengaged

Damaged brake or freespool ass’y

Damaged drum bushing

Damaged gear box

Damaged or inoperative pressed spring

Disengaged freespool

Damaged output shaft

Damaged 1st shaft

Worn or damaged brake

Check battery cable.

Recharge or replace battery

Replace over load protector

Checking all wirings

Replace solenoid

Check winch operation with

an auxiliary switch

Replace motor or carbon brush

Reconnect or replace wiring

Replace solenoid

Replace switch

Replace wiring and tighten.

Engaged freespool

Replace brake or freespool ass’y

Replace drum bushing

Replace gear box

Replace pressed spring

Engaged

Replace output shaft

Replace 1st shaft

Replace or adjust brake

Motor leads crossed

Solenoid control crossed

Remote control or trigger switch

crossed

Long period of operation

Over-load

Damaged or inoperative brake

Reverse electrical connections

to motor

Reverse black and red wires

on the solenoid

Reverse electrical connections

Stop operation to have it cooled

Reduce load

Replace or repair brake

Symptom

Remedy

Possible Cause

Motor runs in one direction

Drum will not freespool

No brake

Brake distance is too long

Winch runs opposite

direction

Motor runs extremely hot