30

© Titan Tool Inc. All rights reserved.

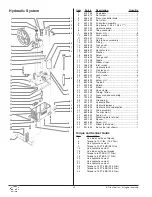

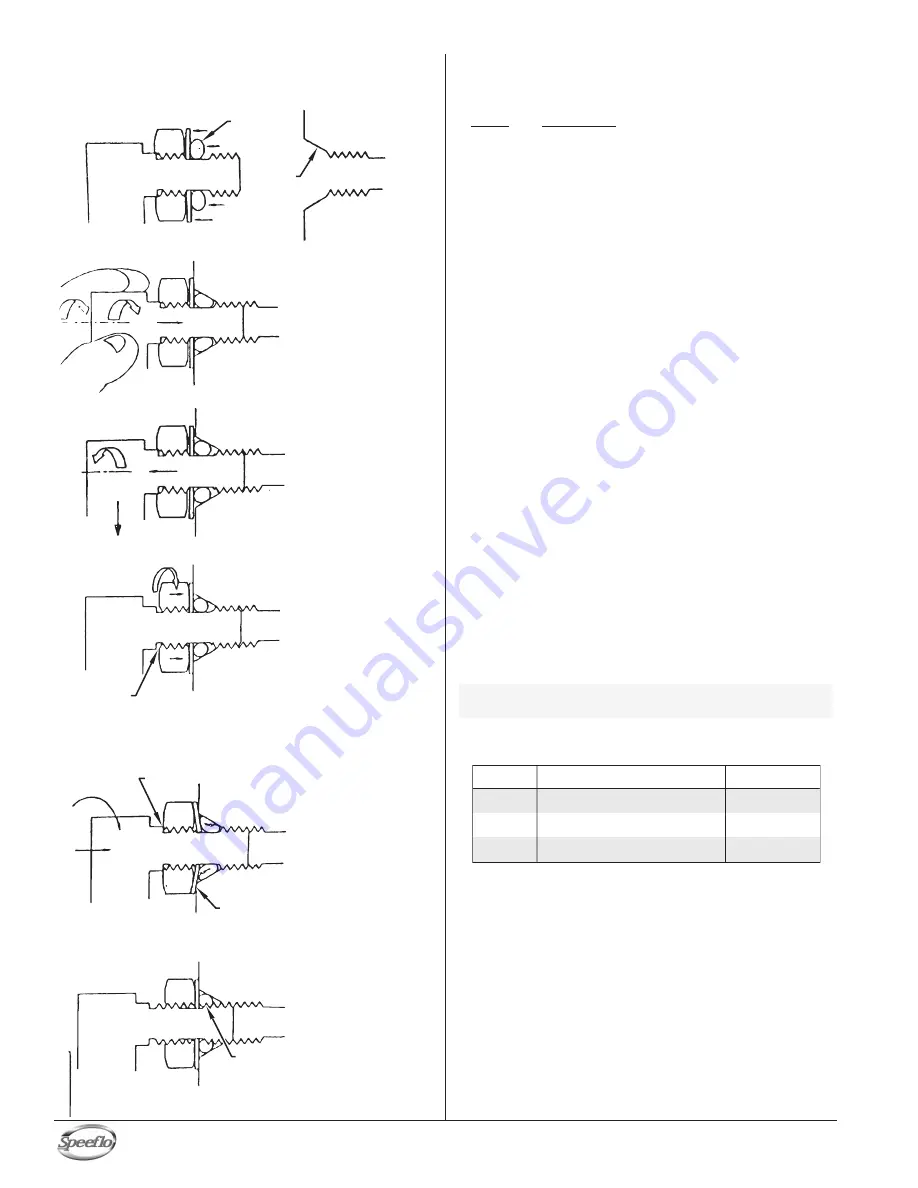

SAE O-Ring Fitting Installation

Steps 1 & 2:

Step 3:

Step 4:

Step 5:

Cautions:

Lubricate

Lubricate

Tighten nut

Recess

gap

No gap

A

lig

n

Hold

this part

stationay

Avoid screwing fitting in too far.

Avoid leaving fitting too far out.

Bent washer allows

for o-ring extrusion

O-ring cut on

thread

Accessories and Service Kits

These items may be purchased separately from your local

Speeflo distributor.

Part #

Description

103-830

5 Gal. Siphon Hose Assembly w/Rock Catcher

1" x 4.5'

103-808

55 Gal. Siphon Hose Assembly w/Rock Catcher

1" x 6.5'

103-627

Rock Catcher

930-004

Paint Filter Element, 0 Mesh (for mastics)

930-005

Paint Filter Element, 5 Mesh (for multicolors

and heavy materials)

930-006

Paint Filter Element, 50 Mesh (for latex and

normal architectural materials)

930-007

Paint Filter Elements, 100 Mesh (for stains,

lacquers and fine materials)

550-100

S-5 Gun w/Tip

550-110

S-5 Gun, Tip, and 1/4” Hose Kit

101-208

Grounding Clamp

101-212

Grounding Wire, 12 Gauge x 25'

314-480

Piston Lube, 8 oz.

314-482

Liquid Shield Plus, 1 quart

430-362

Coolflo™ Hydraulic Fluid, 1 quart

430-361

Coolflo™ Hydraulic Fluid, 1 gallon

975-212

2-Gun Manifold with Ball Valves, 1/4"

975-213

3-Gun Manifold with Ball Valves, 1/4"

975-312

2-Gun Manifold with Ball Valves, 3/8"

975-313

3-Gun Manifold with Ball Valves, 3/8"

808-550

3/8” NPS(M) x 3” hex fitting

Airless Tip Selection

Tips are selected by the orifice size and fan width. The proper

selection is determined by the fan width required for a specific

job and by the orifice size that will supply the desired amount

of fluid and accomplish proper atomization.

For light viscosity fluids, smaller orifice tips generally are

desired. For heavier viscosity materials, larger orifice tips are

preferred. Please refer to the chart below.

The following chart indicates the most common sizes and the

appropriate materials to be sprayed.

Fan widths measuring 8" to 12" (20 to 30 cm) are most

preferred because they offer more control while spraying and

are less likely to plug.

Tip Size

Spray Material

Filter Type

.011 – .013

Laquers and stains

100 mesh filter

.015 – .019

Oil and latex

50 mesh filter

.021 – .026

Heavy bodied latex and blockfillers

5 mesh filter

NOTE: Do not exceed the pump's recommended tip

size.

1. Pull washer and o-

ring back as far as

possible.

2. Lubricate o-ring and

entrance port.

3. Screw fitting in until

washer pushes o-

ring into entrance

and sits flat against

port. (Do not

tighten! - only do this

step hand tight to

compress o-ring into

port!)

4. Back fitting out no

more than one

complete turn to

align as required.

5. Torque nut wrench

tight holding backup

on fitting. This

should expose a

recess gap behind

the nut which can

act as an indicator

that the fitting is

assembled correctly.

(This is a feature for

a specific version of

this fitting only -

which screws into

the cylinder head.

Other fittings, as the

ones which attach to

the hydraulic pump,

assemble the same

but may not have

the indicator.)