Operating the Swing Cart

Use caution when operating the swing cart. Keep

fingers and feet clear of moving parts.

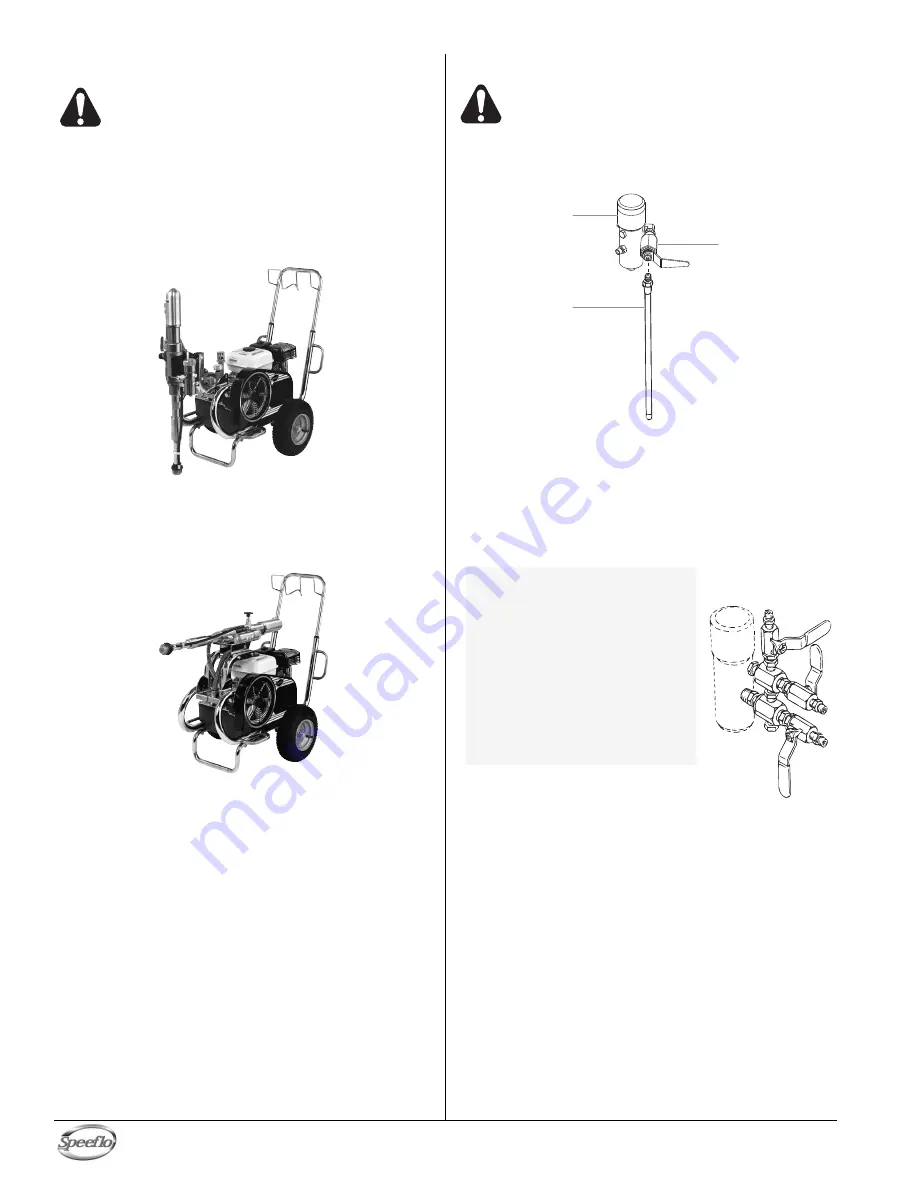

The swing cart allows the motor/pump assembly to be rotated

between two positions.

Position #1: Working Position

The vertical position of the motor/pump assembly is the

working position. This position allows complete submersion of

the siphon tube on the fluid section into a paint bucket. The

maximum height paint bucket that can be used is 28 1/8” (71.4

cm).

Position #2: Transporting Position

The horizontal position of the motor/pump assembly is the

transporting position. This position allows easy removal of the

paint bucket and a sprayer height of 30” (76.2 cm) for ease of

transportation.

Use the following procedure to change the position of the

motor/pump assembly.

1. Holding the handle grip with one hand, pull the locking pin

out of the locking hole on the cart with the other hand.

This allows the motor/pump assembly mounted on the

swing cart frame to move from one position to the other.

2. Let go of the locking pin once it is free of the locking hole.

3. Move the motor/pump assembly to the desired position.

The locking pin is spring loaded and will automatically

engage the locking hole on the swing cart at the new

position.

6

© Titan Tool Inc. All rights reserved.

Setup

Read, understand, and follow all warnings before

starting or operating this sprayer.

1. Make sure the bleed hose is threaded into the bleed

valve. It has factory installed Teflon tape on the fitting and

should be tightened wrench tight.

2. Attach a minimum of 50’ of nylon airless spray hose to the

sprayer. Do not use Teflon tape or thread sealant on the

spray hose connection.

3. Attach an airless spray gun to the spray hose. Do not

attach the tip to the spray gun yet. Remove the tip if it is

already attached.

a. To use two guns, remove the plug from the second gun

outlet on the filter assembly. Connect a hose and gun

to the outlet.

4. Fill the oil cup 1/2 full with Speeflo

Piston Lube (P/N 314-480) supplied

by the factory. This extends packing life.

5. Check the hydraulic fluid level daily before starting the

sprayer. The hydraulic fluid level should be at the “Full”

mark on the dipstick. Refer to the Maintenance section of

this manual for hydraulic system maintenance

instructions.

IMPORTANT: Use of Speeflo's Coolflo™ Hydraulic Fluid

(P/N 430-361) is mandatory in the hydraulic system. Do

not use any other hydraulic fluid. Use of any other

hydraulic fluid may seriously damage the hydraulic

system and will void the warranty.

NOTE: The gas sprayer is

engineered to handle up

to 6 guns with .024" tips

and the electric sprayer

is engineered to handle

up to 3 guns with .019”

tips. For multiple gun

operation, connect a

multiple gun manifold to

the single gun outlet.

Connect a hose and gun

to each outlet. Make

sure the second gun

outlet remains plugged.

Multiple Gun

Manifold

Bleed Valve

Filter

Bleed Hose