© Titan Tool Inc. All rights reserved.

7

6. For gas models, check the engine oil level daily before

starting the sprayer. The gasoline engine oil level is

determined by the engine manufacturer. Refer to the

engine manufacturer’s service manual supplied with this

sprayer.

7. For electric models, use a 20 amp service outlet. Always

locate the electric model within 10 to 15 feet of the service

outlet. Use a short electric cable and a long paint hose.

Any extension cord will create some voltage drop. If an

extension cord is necessary, use only a grounded 3-wire

#12 gauge extension cord.

8. Make sure the sprayer is grounded. All sprayers are

equipped with a grounding lug. A grounding cable (not

supplied) should be used to connect the sprayer to a true

earth ground. Check your local electrical regulations for

detailed grounding instructions. See the Accessories and

Service Kits section near the back of this manual for

grounding cable ordering information.

Proper grounding is important. This applies to

both gas and electric powered models. The

passage of some materials through the nylon fluid

hose will build up a static electric charge, which if

discharged, could ignite solvent vapors present

and create an explosion.

9. Strain all paints with a nylon strainer to ensure trouble

free operation and freedom from frequent cleaning of the

inlet screen and gun filter.

10 Make sure the spray area is well ventilated to prevent

hazardous operation with volatile solvents or exhaust

fumes.

If lacquer or other flammable materials are to be

sprayed, ALWAYS locate the sprayer outside the

immediate spraying area. Failure to do so may

cause an explosion.

11. Locate the sprayer outside the immediate spraying area to

avoid clogged air intake of the engine or electric motor

with overspray.

NOTE: If the sprayer is being operated in an area that

is overloaded by other appliances or low

voltage conditions, it is important to start the

sprayer "unloaded." Tip the electric motor

forward so that the belt is loosened and the

motor starts without full load. This reduces the

amperage draw on starting and may avoid

tripping the circuit breaker.

Preparing a New Sprayer

If this sprayer is new, it is shipped with test fluid in the fluid

section to prevent corrosion during shipment and storage.

This fluid must be thoroughly cleaned out of the system with

mineral spirits before you begin spraying.

IMPORTANT: Always keep the trigger lock on the spray

gun in the locked position while preparing the system.

1. Place the siphon tube into a container of mineral spirits.

2. Place the bleed hose into a metal waste container.

3. Set the pressure to minimum by turning the pressure

control knob fully counterclockwise.

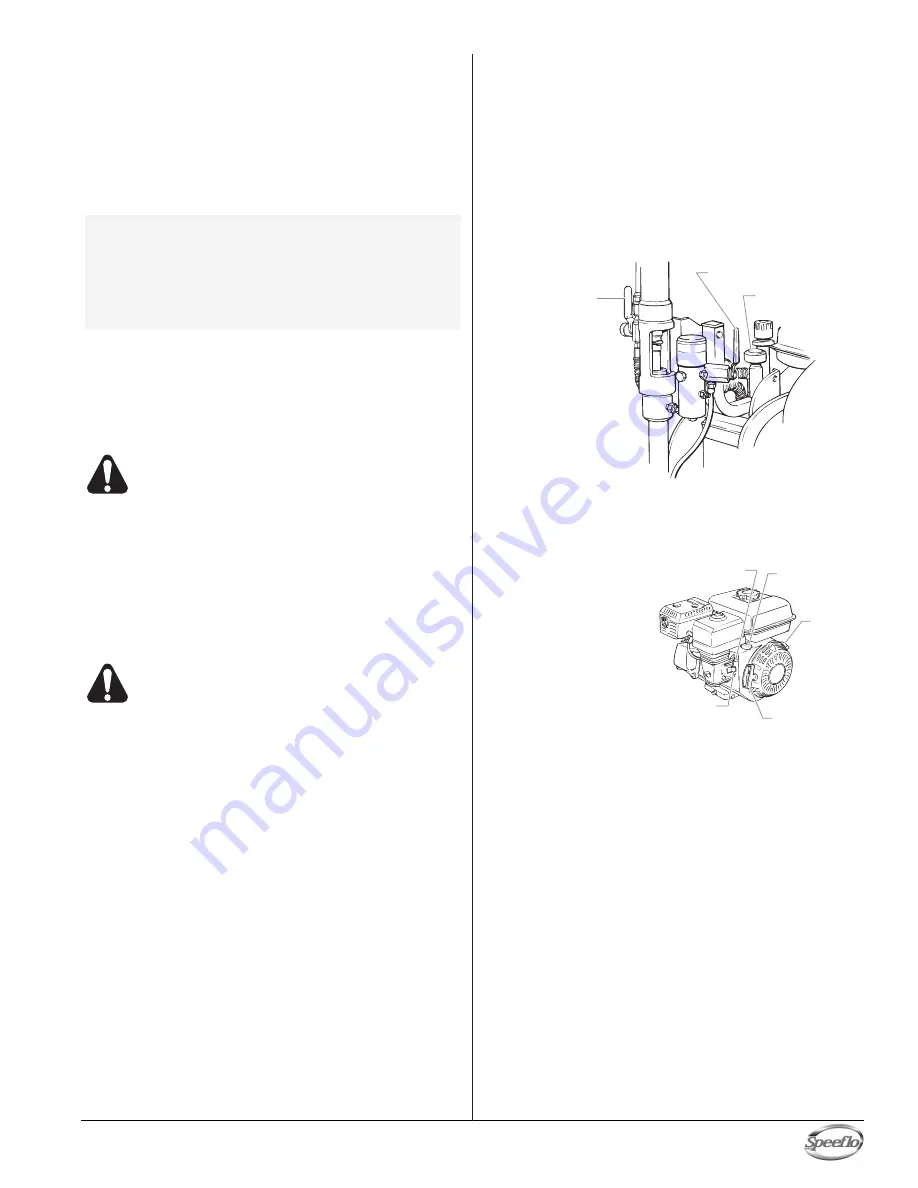

4. Open the hydraulic shut-off valve located on the hydraulic

pressure hose. The handle should be in line with the hose.

5. Open the bleed valve by rotating the bleed valve handle

fully counterclockwise.

6. Start the engine or turn on the electric motor.

a. To start the gas

engine,

• move the fuel

valve lever to

the open

position,

• move the

throttle lever to

its middle point,

• move the choke

lever to the

closed position

for a cold engine or to the open position for a warm

engine,

• turn the engine switch to the ON position, and

• pull the starter rope briskly until the engine starts.

b. To start the electric motor, move the ON/OFF switch to

the ON position.

7. Turn the pressure control knob clockwise approximately

1/3 of the way down to increase pressure until the sprayer

cycles evenly and solvent flows freely from the bleed hose.

8. Allow the sprayer to run for 15–30 seconds to flush the

test fluid out through the bleed hose and into the waste

container.

9. Turn off the sprayer.

a. To turn off the gas engine,

• set the pressure to minimum by turning the pressure

control knob fully counterclockwise,

• move the throttle lever to the slow position, and

• turn the engine switch to the OFF position.

b. To turn off the electric motor,

• set the pressure to minimum by turning the pressure

control knob fully counterclockwise,

• move the ON/OFF switch to the OFF position.

Fuel Valve

Lever

Choke Lever

Engine

Switch

Throttle

Lever

Starter Rope

Hydraulic Shut-off

Valve (in open

position)

Pressure Control

Knob

Bleed Valve