205B Series User’s Manual

3

118124-001-Rev.A

2.4.1 POLARITY REVERSAL 1kV TO 5kV

OUTPUT MODELS

The screwdriver-rotatable POLARITY SELECTOR

switch (S3) is accessible at the rear panel of the

unit. Rotate as required for the desired polarity.

2.4.2 POLARITY REVERSAL 10kV TO 50kV

OUTPUT MODELS

The polarity is reversible by means of an internal

polarity module, which is easily accessible upon

removal of the top cover. Polarity is reversed by

removing two diagonally opposed Philips head

screws, lifting up on the module, rotating it 180°,

and then reinserting it. A safety interlock

automatically ensures that the high voltage cannot

be turned on unless this module is fully seated and

installed in one polarity position or the other.

A remote polarity indication is provided at J107

(PROGRAMMING/MONITOR)

connector

jack

located on the rear panel of the unit (see section

4.3).

SECTION III: LOCAL OPERATION

CAUTION! THIS UNIT CAN STORE

HAZARDOUS VOLTAGE. COMPLETELY

DISCHARGE HIGH VOLTAGE AT REAR PANEL

GROUND TERMINAL BEFORE ATTEMPTING

REMOVAL OF THE HIGH VOLTAGE CABLE

3.1

FRONT PANEL CONTROLS

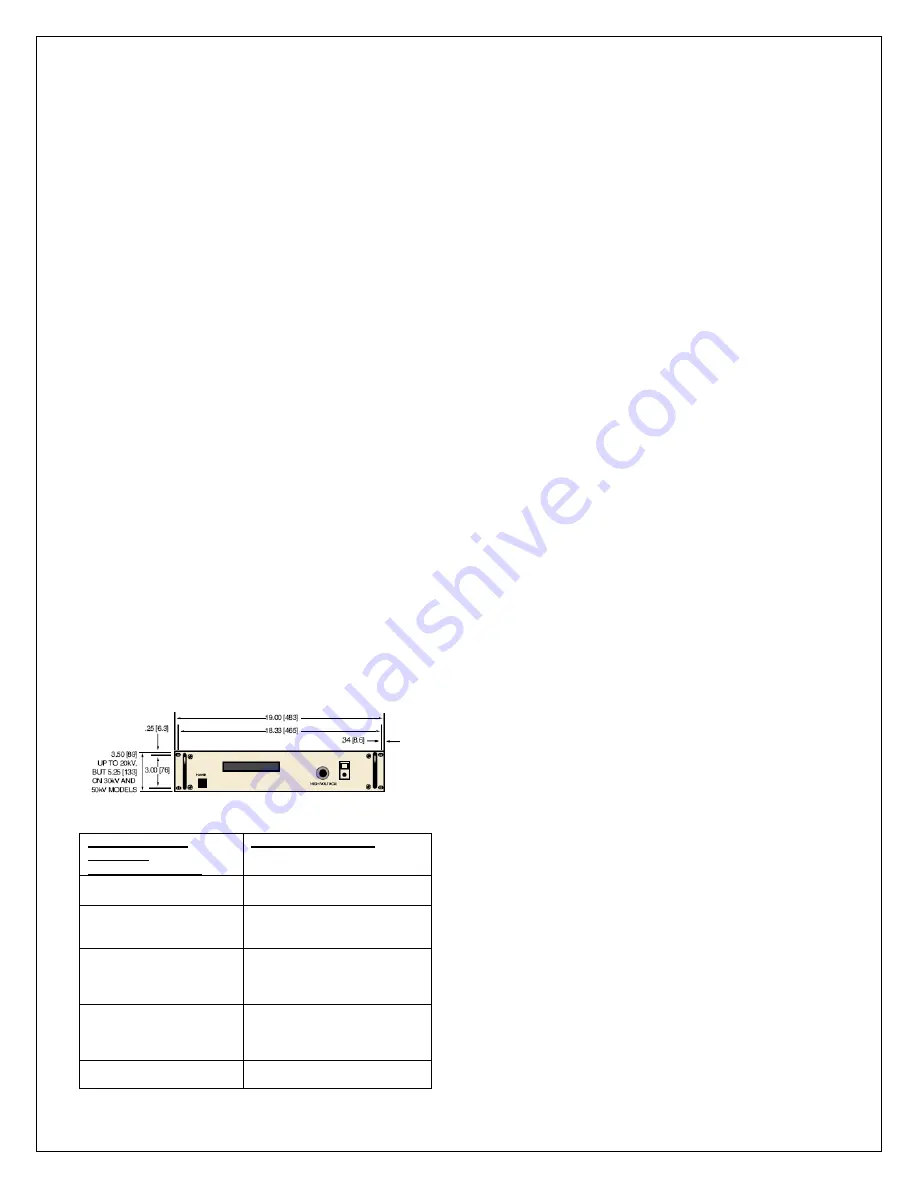

Figure 4.1 below is the typical layout of the 205B

Series front panel

Figure 3.1

SWITCHES/PUSH

BUTTONS/

INDICATORS/DIALS

FUNCTION/PURPOSE

POWER ON-OFF

Enables and disables AC power

kV/mA SWITCH

Controls the output parameter

that the front panel display

exhibits

VOLTS

Illuminated when the meter is

displaying the output current

mA

Illuminated when the meter is

displaying the output current

HIGH VOLTAGE

CONTROL

Adjusts the high voltage output

3.2

PROGRAM CONTROL SWITCH

The front panel controls of the unit are only

functional for programming purposes when the

units’ rear panel PROGRAM CONTROL switch

(S101) is in the LOCAL position. However, if the

unit receives a voltage programming command

while S101 is in the Remote Analog position, the

switching of S101 to its LOCAL position afterwards

will then cause the value of that programming

command to take effect.

3.3

LOCAL OPERATION

The local mode of the 205B Series provides all of

the control and monitoring functions available with

front panel control.

SECTION IV: REMOTE ANALOG OPERATION

CAUTION! THIS UNIT CAN STORE

HAZARDOUS VOLTAGE. COMPLETELY

DISCHARGE HIGH VOLTAGE AT REAR PANEL

GROUND TERMINAL BEFORE ATTEMPTING

REMOVAL OF THE HIGH VOLTAGE CABLE

4.1

PROGRAM CONTROL SWITCH

Before a unit can be programmed with a remote

analog (0 to +5VDC) signal, it must be configured

by setting its rear panel PROGRAM CONTROL

switch (S101) in the REMOTE ANALOG. Note:

All other monitoring and non-programming

functions remain active, regardless of the S102

position.

4.2

REMOTE CONTROL

The high voltage output can be remotely

programmed from an external voltage source. A 0

to +5VDC programming voltage applied to Pin 6 of

the J107 (PROGRAMMING/MONITOR) connector

jack on the rear panel will remotely program the

high voltage output from zero to maximum voltage.

Programming can also be accomplished using a

potentiometer connected between Pin 4 (+5VDC),

Pin 7 (GND) with the wiper connected to Pin 6.

The potentiometer should be a low temperature

coefficient wirewound or cermet type of 5k

ȍ

to

20k

ȍ

resistance value. The output will then be in

proportion to the wiper position.

4.3

ANALOG MONITORING SIGNALS

Analog monitoring signals of 0 to +5VDC via 10k

ȍ

are provided, which are linearly proportional to the

unit’s output voltage and current. A TTL-

compatible logic TRIP input, a +5VDC reference

voltage output and an NPN open collector polarity

indicator are all available at J107.