LPX-200

Industrial Imaging System

2-5

Chapter 2: Preparation for Use and Shipment

SPECIFICATIONS

The following tables illustrate the physical, operational, and

environmental specifications for each component of the

LPX-200 System. Conformance with these specifications

ensures maximum system performance, and reduces the

chances of mechanical breakdown and personnel hazard.

Specifications - General System

The following outlines the general operating and

environmental limits of the LPX-200 System.

❏

Line Voltage * ____________ 100 to 130 VAC - 50/60 Hz, 20

amps (maximum); or 200 to 250

VAC - 50/60 Hz, 10 amps

(maximum)

❏

Operating Potential ________ 10kV to 200kV @ 0.1 to 10.0

mA, 900 Watts maximum

❏

Duty Cycle ______________ 100%

❏

Operating Temperature Range -30

°

F to 120

°

F (Ambient)

-34

°

C to 49

°

C (Ambient)

❏

Humidity ________________ 0 to 100% relative humidity

❏

Stabilization ______________ kV and mA remain within 1% of

set levels. Line voltage varied

from 100-130/200-250 VAC.

❏

Storage Temperature Range _ -65

°

F to 160

°

F (-54

°

C to 71

°

C)

*

Line voltage selection is automatic. The system is

operable from either line voltage range without any

switch or jumper configuration.

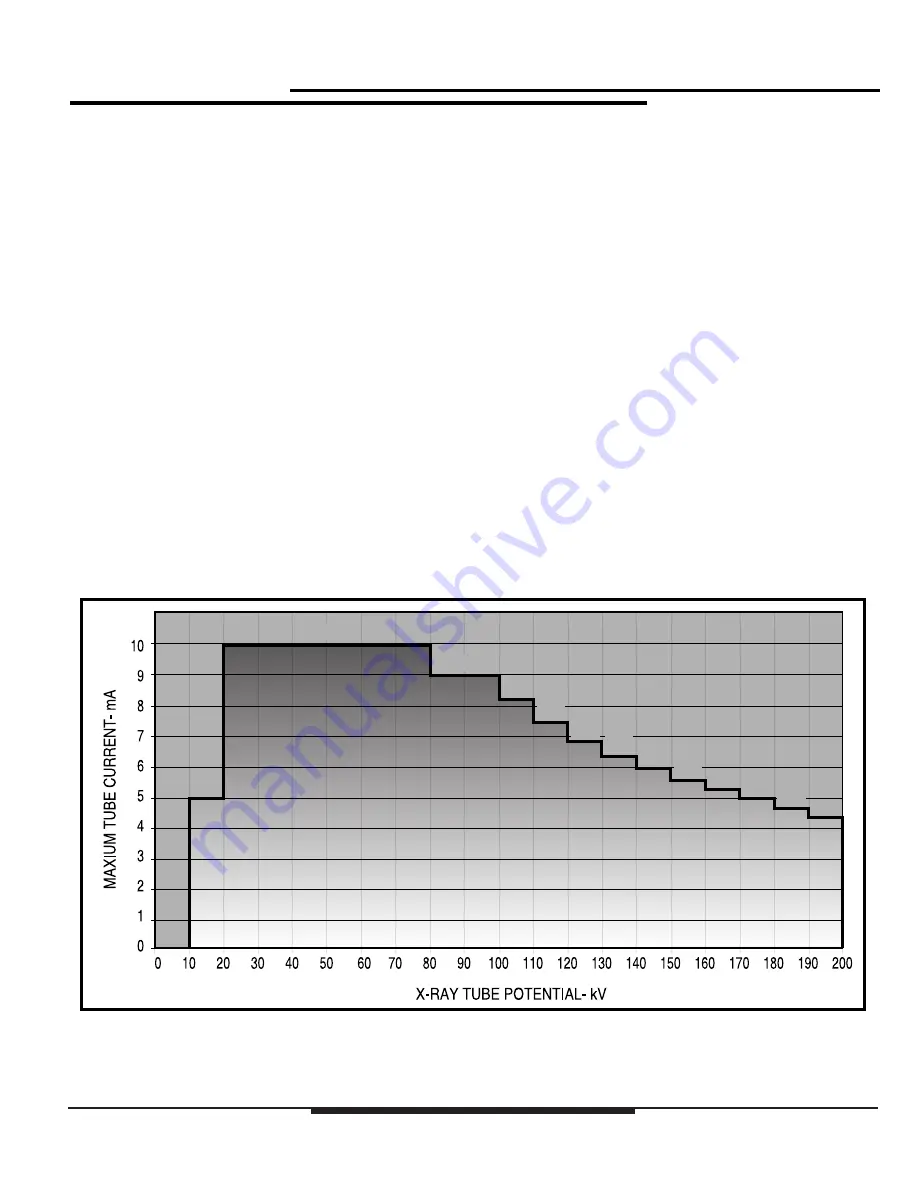

Figure 2-3:

LPX-200 Maximum Tube Current

5.0

10.0

9.0

8.2

7.5

6.9

6.4

6.0

5.6

5.3

5.0

4.7

4.5