DF/FF MANUAL 118002-001 R

ev B

WARNING

Line voltage is present whenever the

power supply is connected to external

line voltages. Be sure to disconnect

the line cord before opening the unit.

allow 5 minutes for internal

capacitance to discharge before

removing any cover

.

When K1 is energized, voltage is applied

to main rectifier bridge power module

CR1. Through the output of the diode

module, rectified AC is supplied to filter

Capacitor C1, a screw terminal type large

can electrolytic. C1 is initially charged

through inrush limiting circuitry located

on the Filament PWB. An LC circuit

comprised of HF film capacitor C2 and an

air core inductor L2 filter HF noise from

inverter.

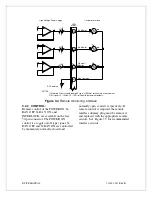

4.2

INVERTER

The inverter is an H bridge hybrid

topology. Current mode control is used for

driving the inverter. Two half-bridge

IGBT modules are used as switches in H

Bridge. These IGBTs provide high

frequency switching to control the

primary current flow. Typically they

operate at approximately 18kHz.

The IGBT driver board provides the gate

control of the switches. The system

control board generates gate drive control

signals. The IGBT gate driver PWB

provides the required gate voltages and

offsets.

4.3

HIGH VOLTAGE

TRANSFORMER

The output of the High Frequency Quasi-

resonant Inverter is connected to the

primary of the High Voltage Transformer.

The High Voltage Transformer is a step

up type. Typical secondary voltages are in

the range of 3kV to 16kV depending upon

output voltage ratings.

4.4

HIGH VOLTAGE

ASSEMBLY

The High Voltage Assembly will vary

depending upon the model ordered. The

circuitry typically consists of a series

arrangement of full wave voltage

doublers.

A high bandwidth resistive/capacitive

divider provides voltage feedback for

regulation and monitoring. A sense

resistor connected at the low voltage end

of the High Voltage Rectifier provides

current feedback for regulation and

monitoring.

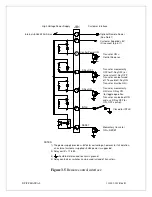

4.5

FRONT PANEL/SYSTEM

CONTROL PWB

Auxiliary DC voltages are generated in

low voltage power supply section of the

Front Panel/System Control PWB.

Front panel LEDs provide status

indication of the necessary diagnostics

needed for recognizing the

operation/shutdown mode of the

generator. Front panel LEDs display the

following information:

CONTROL POWER ON

EXT. INTERLOCK OPEN

OVER VOLTAGE

OVER POWER

MA RGLT ERROR

KV MIN ERROR

FIL CURR LIMIT

EXT INTERLOCK CLOSED

HIGH VOLTAGE ON

OVER CURRENT

KV RGLT ERROR

LEAKAGE LIMIT /TEMP

ARC

Summary of Contents for X3645

Page 1: ...DF FF MANUAL 1 118002 001 Rev B ...

Page 2: ...DF FF MANUAL 2 118002 001 Rev B ...

Page 28: ...DF FF MANUAL 118002 001 Rev B ...

Page 29: ...DF FF MANUAL 118002 001 Rev B ...

Page 30: ...DF FF MANUAL 118002 001 Rev B ...

Page 31: ...DF FF MANUAL 118002 001 Rev B ...

Page 32: ...DF FF MANUAL 118002 001 Rev B ...

Page 33: ...DF FF MANUAL 118002 001 Rev B ...

Page 34: ...DF FF MANUAL 118002 001 Rev B ...

Page 35: ...DF FF MANUAL 118002 001 Rev B ...

Page 36: ...DF FF MANUAL 118002 001 Rev B ...

Page 37: ...DF FF MANUAL 118002 001 Rev B ...

Page 38: ...DF FF MANUAL 118002 001 Rev B ...

Page 39: ...DF FF MANUAL 118002 001 Rev B ...

Page 40: ...DF FF MANUAL 118002 001 Rev B ...