17

4.3.16

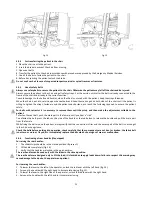

Patient transport during stair climbing

To avoid any risk to the safety of the patient, during transport on the stairs it is necessary that at least two operators are

employed. In the event that more people are required to ensure safe operation of the chairs, please refer to the section

about USE OF ADDITIONAL ASSISTANCE to find the right position that each operator must occupy.

To avoid injury, before lifting the chair with the lifting handles, make sure that they are always locked in place.

1.

Bring the chair at the end of the stairs with the back of the patient facing the stairs.

2.

Operator foot side: Open the lifting handles at foot end.

3.

Operator head end: Open the handles to lift the head end.

4.

The operator at the foot side is facing the stairs. The operator at the head side may be towards the patient, for a better

control of the patient, or forwards, for a better view of the stairs and to be able to cope better maneuvering in case of

obstacles.

5.

Both operators using the handles at the head and foot end, lift the chair at the same time adhering to proper lifting

techniques. Carry the chair slowly climbing the stairs without any obstruction.

Even if the operator placed at the head side can be turned in both directions, while lifting and transporting the chair, you

must follow all protocols for chairs transport.

USE OF ADDITIONAL ASSISTANCE

To avoid any risk to the safety of the patient, during transport on the stairs it is necessary that at least two operators are

employed. In the event that more people are required to ensure safe operation of the chairs, please refer to the section

about USE OF ADDITIONAL ASSISTANCE to find the right position that each operator must occupy.

4.4

Troubleshooting

PROBLEM

CAUSE

REMEDY

The device doesn’t release from the closed

or open position during functioning or

closing phase

The functioning geometry is

compromised or seized; the safety

devices have not been removed

After performing adequate lubrication,

check if the problem persists. If so put

the device out of service and contact the

service centre.

Difficulties in the extraction and insertion

of telescopic handles or rear handles

Sediments in the slides area or

yielding of the aluminium profile

Carry out thorough cleaning. If the

problem persists, do not use the device

for handling involving the ascent of the

stairs and contact the service centre.

Injuries to the structure

Misuse and inadequately trained

staff

Put the device out of service and contact

the service centre

5

MAINTENANCE AND CLEANING

5.1

Cleaning

Failure to carry out the correct cleaning routine could increase the risk of cross infection, due to presence of body fluids

and/or residuals.

The operator must always wear adequate personal protection such as gloves and mask etc. during all checking and

cleaning procedures.

The exposed metal parts are usually treated and/or painted in order to increase their resistance.

Clean the exposed parts with water and delicate soap then dry with a soft cloth; never use solvents or stain removers. If

disinfection is required, use a quaternary or phenolic disinfectant diluted in the proportions specified by the manufacturer

that does not have solvent or corrosive action on the materials.

Do not use pressure washing, steam or ultrasonic. Rinse thoroughly with warm water, the water temperature must not

exceed 40° C, verifying to have eliminated all traces of detergent, which could be degrading or compromising the integrity

and durability of the device.

The water pressure must not exceed 3 bar. Indeed, water penetrates the joints and removes the oil, creating the risk of

corrosion of components.

Dry accurately with a soft cloth and taking care to avoid water going inside the chair; do not use flames or other sources of

direct heat.

Failure to comply with instructions may void the warranty.

Summary of Contents for EVA

Page 6: ...6 Fig 1 Fig 2 ...