11

U s e r I n s t r u c t i o n s - E n g l i s h

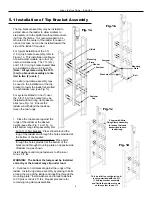

Washer

Fastener

U-Bolt

Mounting

Plate

Mounting

Bolt

Typical Installation

90 Degree Installation

Fig. 4a

90 Degree Installation

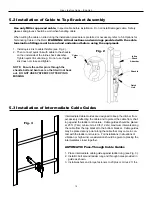

Note: High wind areas permit rotating the end of this cable

guide 90 degrees in either direction. When installation requires

this option, cable guides should be alternated from left to right

throughout the length of the system.

1. Remove fasteners from cable guide end.

2. Rotate end 90 degrees and reinsert fasteners (see Fig. 4b).

3. Torque fasteners to 20 plus or minus 2 ft. lbs.

4. To install cable guide with 90 degree end, follow above pro-

cedure except insert U-bolt through the two holes furthest

from the cable end on the guide bracket.

Fig. 4b

MANUAL Pass-Through Cable Guides

Typical Installation

1. Place cable guide on top of ladder rung (see Fig. 4a).

2. Install U-bolt around underside of ladder rung and through holes

provided in cable guide.

3. Install washers and torque fasteners to 20 plus or minus 2 ft. lbs.

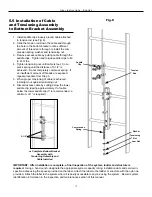

5.4 Installation of Bottom

Bracket Assembly

WARNING: Inspect the bottom bracket assembly.

Do not use if there are any damaged or missing

components. Missing, damaged or omitted com-

ponents can result in the bracket slipping under a

load.

1. Place bottom bracket against the rungs of the lad-

der at the desired location aligning the bracket so

that the ladder rung is centered between the two

vertically placed holes in the bottom of the bracket.

(see Fig. 5).

2. Install bolts through holes in bottom of bracket and

through plate on opposite side, including washers,

as shown. Torque fasteners to 20 plus or minus

2 ft. lbs.

3. Install U-bolts around ladder rung at top of bracket

and through mounting plate. Install washers and

torque fasteners to 20 plus or minus 2 ft. lbs.

Fig. 5

Summary of Contents for MILLER Vi-Go

Page 1: ......