16

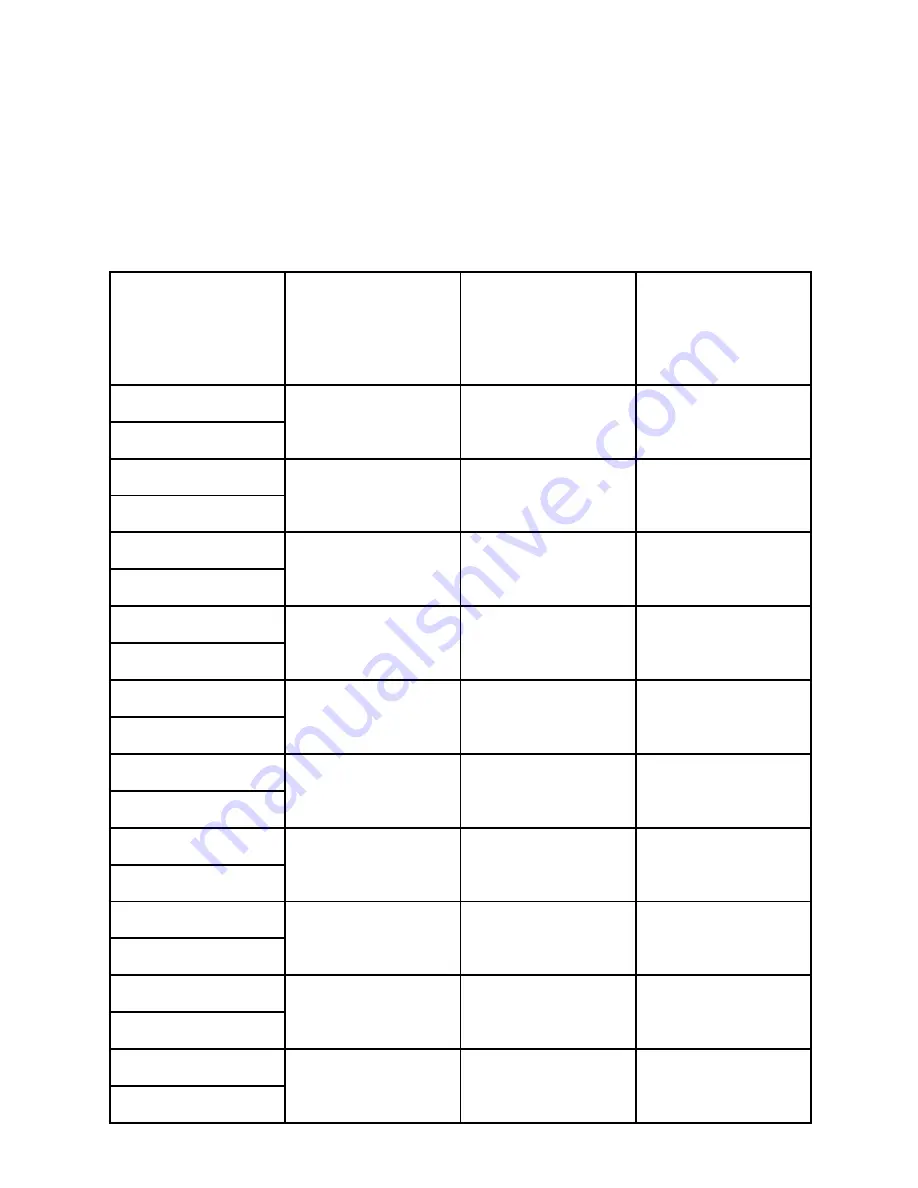

INSPECTION DATE

DATE D’INSPECTION

FECHA DE INSPECCIÓN

INSPECTION

ITEMS NOTED

P

OINTS NOTÉS

LORS DE L’INSPECTION

P

UNTOS DE INSPECCIÓN

RELEVANTES

CORRECTIVE

ACTION

A

CTION CORRECTIVE

M

EDIDA CORRECTIVA

MAINTENANCE

PERFORMED

ENTRETIEN EFFECTUÉ

M

ANTENIMIENTO

REALIZADO

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

DATE OF MANUFACTURE:

_________________________________________________

DATE DE FABRICATION / FECHA DE FABRICACIÓN

MODEL NUMBER:

________________________________________________________

NUMÉRO DE MODÈLE / NÚM. DE MODELO

DATE PURCHASED:

______________________________________________________

DATE D’ACHAT / FECHA DE COMPRA

Inspection and Maintenance Log

Registre D'inspection et D'entretien

Registro de Inspección y Mantenimiento

Summary of Contents for MILLER Vi-Go

Page 1: ......