7

Panther HIP-PAC

4. The air supply connection using the 1/4 inch male-

to-male adapter illustrated in Method 2 is also ap-

proved for use with Methods 3 and 4.

a. Method 1 is preferred when only one length of

hose is required, since it allows the hose to be dis-

connected from the air supply.

b. Method 3 is preferred when multiple lengths of

hose (maximum of three) are required, eliminating

the cost of quick-disconnect couplers at the hose

junctions.

5. Pressurize and check for leaks with a bubble-type

leak detector. If leaks are detected:

a. Disassemble and repeat steps 3 through 5.

b. If the leaks persist, remove the hose from ser

-

vice and have repairs made by a SPERIAN-certified

technician.

WARNING

Always verify that the swivel nut gas

-

kets are in place and undamaged before

assembly. Missing or damaged swivel

nut gaskets may allow contaminants to

leak into the system causing illness or

death.

C. Donning

WARNING

• Always don, remove, and fit check the

respirator in a safe, uncontaminated

area.

• The regulator must be attached to the

Panther HIP-PAC air cylinder before

connecting the air line hose to the air

supply. Using the supplied air line with-

out the regulator being attached to the

cylinder could result in loss of air, caus

-

ing illness or death.

• Verify that the air cylinder valve is

turned off before connecting to the air

supply. Using the Panther HIP-PAC with

the air cylinder turned on while connect-

ed to the air supply will cause loss of air

in the cylinder, resulting in reduced es-

cape time in case of an emergency.

• Always disengage the regulator from

the facepiece and return it to the waist

belt-mounted receiver when not in use.

This will prevent contaminants from

entering the regulator outlet port. Dirt,

dust, and water may enter the regulator,

causing it to malfunction.

• Failure to comply with this Warning

may lead to serious personal injury, se-

rious illness, or death.

1. Verify that the air cylinder valve is turned off.

2. Verify that the bypass is in the OFF position and

that the cylinder gauge reads full.

3. Depress the shutoff button on the second stage

regulator.

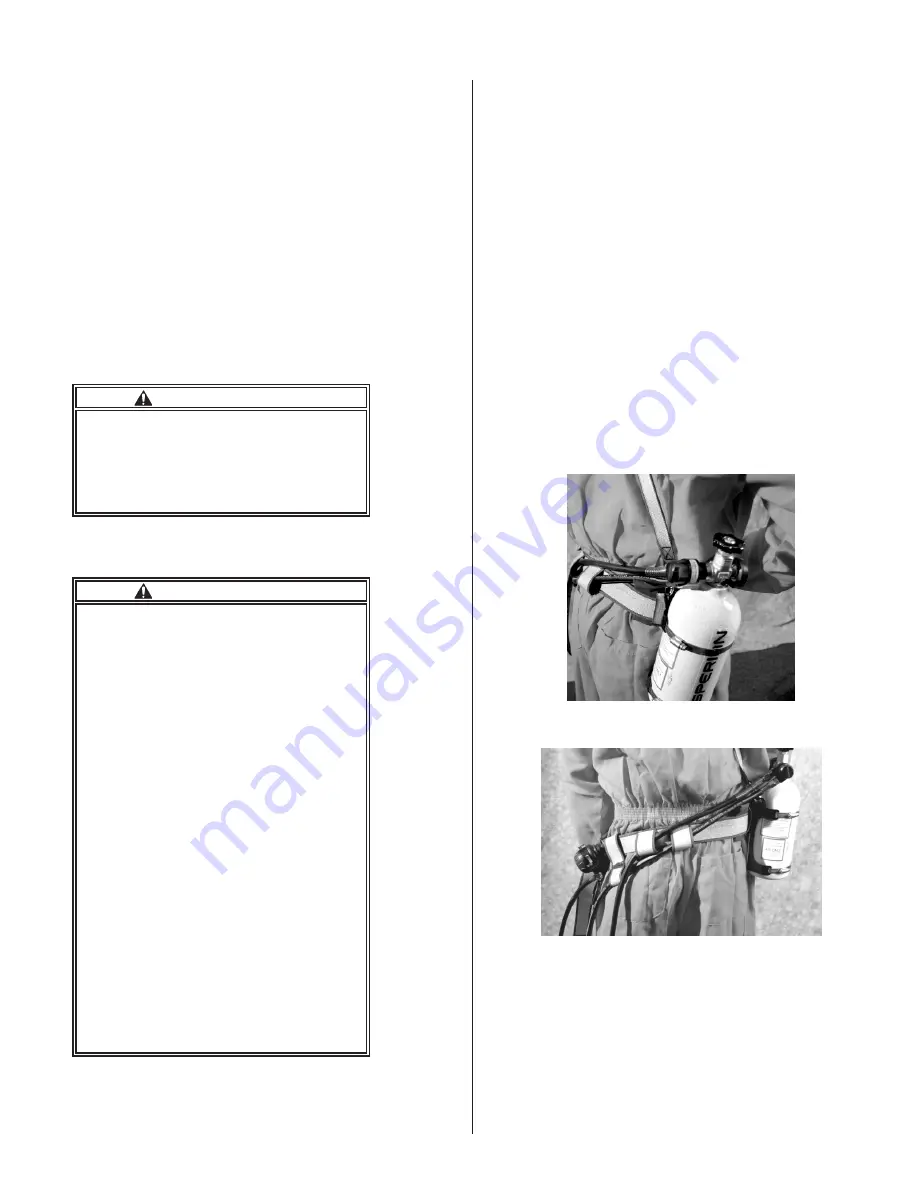

4. Ensure that the waist belt and hip pad (if used) are

properly positioned on the tank mounting bracket belt

loop. See Figure 3.

5. Insert the air line hose through the first waist belt

loop on the back of the waist belt and the restraint

sleeve located on the waist belt. See Figure 4.

6. Route the second stage hose through the second

loop on the back of the waist belt. Position the second

stage hose so that it routes under your left arm. (If the

hose is too tight, adjust the cylinder nearer the small

of your back.)

NOTE

The following steps 7-10 do not apply to

the 5-minute and 10-minute nylon harness

assembly, P/N 975230.

Figure 3. Waist Belt and Hip Pad Position

Figure 4. Routing of Hoses

7. Ensure that the regulator receiver is attached to the

waist belt just behind the snap hook.

8. Ensure that the waist belt is laced properly through

the D-ring slide and the snap hook. See Figure 5.