SURVIVAIR Opti-Fit

™

Convertible Facepiece

34

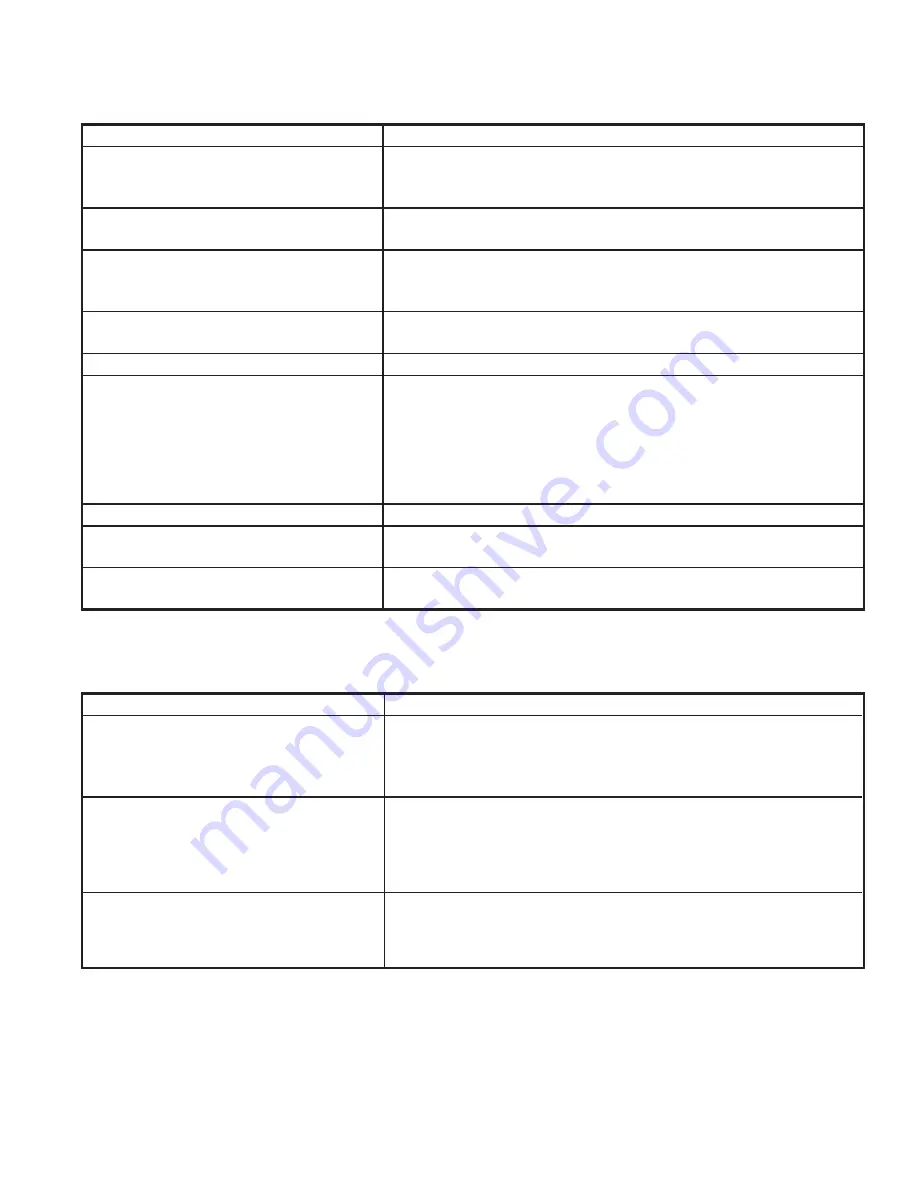

XIV. RESPIRATOR INSPECTION TABLES

General Inspection Table

The following table lists general inspection steps to be followed for all respirator configurations (APR, SAR, PAPR).

COMPONENT

LOOK FOR

FACEPIECE LENS

1. Nicks, scratches, or abrasions that could impair visibility.

2. Deep gouges or cracks which could reduce impact resistance.

3. Anti-fog coating in need of replacement.

FACEPIECE RIMS

1. Deformed, cracked, or broken.

2. Loose screws. Do not overtighten.

FACEPIECE SKIRT

1. Cuts, gouges, or punctures.

2. Tears or nicks in the sealing area.

3. Deterioration from age, heat, or contamination.

FACEPIECE HEADSTRAP

AND BUCKLE STRAPS

1. Abrasions or nicks.

2. Deterioration from age, heat, or contamination.

FACEPIECE BUCKLE

Crushed, bent, broken, or corroded.

FACEPIECE INLET NOZZLE

AND NOZZLE ADAPTER

1. Heat or impact damage.

2. Nicks, cracks, tears, or creases in the exhalation valve. Remove the valve

cover to inspect the exhalation valve.

3. Nicks, cracks or dents in the exhalation valve seat.

4. Sticking exhalation valve. Exhale a few times to test. The valve must close

after each exhalation. Valves that fail to close must be replaced.

5. Cuts, nicks, abrasions, or excess stretching to the Nozzle Adapter O-rings.

O-RINGS/TWIN SEALS

Cuts, nicks, abrasions, or excess stretching.

CARTRIDGE CONNECTORS

1. Cracks, heat, or impact damage.

2. Cuts, nicks, or abrasions on connector sealing flange.

HEADNET

1. Signs of deterioration, weakening, and wear in the the Headnet and straps.

2. Unraveled or loose stitching.

Additional Inspection Table for Supplied Air Respirators (SAR)

For supplied air respirators (SAR), the following inspection steps should be followed in addition to the general inspection

steps listed in the General Inspection Table above.

COMPONENT

LOOK FOR

BREATHING TUBE

(ALL CF-SAR CONFIGURATIONS)

1. Cuts, nicks, cracks, punctures, or tears that may reduce the level of protection.

2. Age or heat induced cracking, checking, or hardening.

3. Crushed, broken, or cracked connectors.

4. Tube is securely attached to the connectors and the hose clamps are tight.

Air Line Hoses (all CF-SAR configurations)

1. Fittings corroded, cracked, or leaking.

2. Cuts, nicks, cracks, punctures, age or heat induced cracking, checking,

abrasions, blistering, holes, crushing, kinking, or hardening.

3. Tightness of connectors and quick couplers.

4. Swivel nut gaskets in place and undamaged.

Belt (all CF-SAR configurations)

1. Webbing color change, excessive wear, fraying, cuts, nicks, or broken

stitching.

2. Buckle damaged or corroded.

3. Loose hardware.