Instruction manual for compressor type HLF2/77

Page 10

MAINTENANCE ROUTINES

The following is a guideline for a normal maintenance schedule. However, the compressors operating

conditions vary widely from installation to installation and it is therefore important to adapt the

maintenance schedule to the experience of the individual operator.

The following schedule applies to automatically monitored and manually operated installations alike.

After the first 200 hour operation:

Change lubricating oil. Drain the sump while the oil is warm. Clean the sump thoroughly before filling

with fresh oil.

Daily inspection:

Make a quick general inspection of the whole compressor (in normal operation) and specially check

the following:

1. Lubricating oil level.

2. Compressed air temperature and pressure.

3. Automatic

equipment.

Overhaul routine A (1.000 running hours or every 2 years):

Make sure that overhaul kit no. 3036MK2 and 3037MK2 are in stock before starting overhaul of

compressor according to Routine A - 1.000 hour service. Please follow installation instructions

included in the kit.

1. Replace lubricating oil.

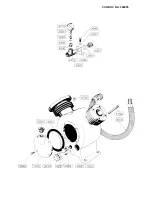

2. Remove the valves from both cylinders. Check for carbon deposits. Dismantle the valve for

cleaning and repair if necessary.

Use spare part kit no. 3036MK2 and 3037MK2 to overhaul

valves.

All valve gaskets should be replaced with new parts at assembly.

3. Inspect the flexible coupling between compressor and motor.

4. Check all bolts and nuts for proper tightness. Also check vibration dampers and hose connections

if the unit is flexibly mounted. Check that no oil has come in contact with the rubber elements in

the vibration dampers.

5. Function-test the safety valve. Start the compressor, and slowly close the stop valve on the

compressed air line. The air pressure should not exceed max. working pr 10%. The

safety valves are sealed and the setting should not be adjusted. If the valves are malfunctioning or

open at wrong pressure, the safety valves should be replaced.

6. Check all pipe connections (compressor running).

7. Check that all automatic equipment is functioning correctly.

8. Change suction air filter, insert (Part no. 8451).

CCG DOC NO. 346055

Summary of Contents for HLF2/77

Page 1: ...HLF2 77 INSTRUCTION MANUAL AIR COMPRESSOR GB SPERRE CCG DOC NO 346055 ...

Page 4: ...Instruction manual for compressor type HLF2 77 Page 3 CCG DOC NO 346055 ...

Page 18: ...CCG DOC NO 346055 ...

Page 19: ...CCG DOC NO 346055 ...

Page 20: ...CCG DOC NO 346055 ...

Page 21: ...CCG DOC NO 346055 ...

Page 22: ...CCG DOC NO 346055 ...