Instruction manual for Water-cooled Air Compressor HV2/210 - 13 -

7. Replacement Parts List - Water Cooled Air Compressor - HV2/210

Part Qty. Description

No.

1012

1

Crankcase

1038

1

Crankcase cover

1041

1

Crankcase cover - dipstick side

1058

1

Bearing housing - flywheel side

1062

1

Bearing housing - lub. oil pump side

1076

1

Flywheel

1103

1

Cylinder block

1153

3

Main bearing shell cups

1163

4

Bearing shell cups, pair

1171

1

Cooler cover - Pos. 1

1175

1

Cooler cover - Pos. 3

1231

1

Frame - bursting plate

1255

1

Cylinder head

1297

1

Air filter duct

1316

2

Valve cover, HP

1318

1

Valve cover, LP suction side

1319

1

Valve cover, LP delivery side

1330

1

Flywheel nut

1366

1

Non return valve cover

1382

1

Coupling flange

1414

1

Connecting rod, LP

1415

1

Connecting rod, HP

1440

2

Inspection hole cover

1441

1

Inspection hole cover with 1/2" hole

1463

2

Clamping piece, HP valve

1471

1

Clamping piece, LP suction valve

1472

1

Clamping piece, LP delivery valve

1516

1

Counterweight

1530

1

Blind plate

2012

1

Crankshaft

2998

1

Non return valve

3245

1

Valve unloader, complete

3304

1

Unloader cover

3311

1

Unloader cylinder

3318

1

Unloader piston

3329

4

Big-end bearing bolt

3335

4

Big-end bearing nut

3340

4

Big-end bearing split pin

3384

1

Piston, LP

3398

1

Piston, HP

3446

1

Connector - pump

3465

1

Gudgeon pin, LP

3468

1

Gudgeon pin, HP

3486

2

Oil scraper ring, LP

3505

4

Compression ring, HP

3519

2

Compression ring, LP

3533

1

Oil ring, HP

3544

1

Oil ring, LP

3577

1

Ball - lub. oil pump

3583

1

Valve spring - lub. oil pump

3606

1

Adjusting screw - lub. oil pump

3634

1

Oil level gauge glas

3643

1

Pressure gauge board

3654

2

Cooler unit

3677

1

Key

Part Qty. Description

No.

3696

3

Cap nut - clamping screw

3697

1

Cap nut - lub. oil pump

3700

1

Breaher valve

3713

1

Air filter unit, complete

3718

1

Air filet insert

3722

1

Oil strainer

3728

1

Oil strainer mesh

3731

1

Oil strainer holder

3741

2

Clamping screw, HP

3742

1

Clamping screw, LP

3746

1

Dipstick

3770

2

Pressure gauge, C.W./lube oil

3771

1

Pressure gauge, LP

3773

1

Pressure gauge, HP

3775

2

Spacer

3781

1

Thermometer

3783

1

Nipple - thermometer

3810

4

Seeger ring

3821

1

Gudgeon pin bearing, LP

3822

1

Gudgeon pin bearing, HP

3832

2

Big-end bearing shell, pair

3852

1

Sealing ring - lub. oil pump

3861

1

Sealing ring - main shaft

3906

5

Valve gasket

3909

2

Valve gasket

3921

2

Main bearing end

3922

1

Main bearing guide

3925

4

Copper washer

3927

8

Copper washer

3928

5

Copper washer

3929 22

Copper washer

3930

6

Copper washer

3932

4

Copper washer

3934

2

Copper washer

3937

4

Lock washer

3946

4

Screw - lub. oil pump

3950

2

Screw - pressure gauge panel

3960

1

Bursting plate

3965

1

Internal lub. oil tube set

3974

4

O-ring - air coolers

3979

1

O-ring - valve unloader

4028

2

Gasket - crankcase / cylinder block

4033

2

Gasket - crank case cover

4034

1

Gasket - bearing housing, oil pump side

4035

1

Gasket - bearing housing, flywheel side

4053

1

Gasket - air outlet flange

4057

2

Gasket - HP valve cover

4058

2

Gasket - LP valve cover

4059

1

Gasket - lub. oil pump

4068

4

Gasket - bursting plate

4070

1

Gasket - cylinder cover

4085

1

Gasket - air filter duct

4099

3

Gasket - cooler cover

4132

1

Backnut

4142

1

T-joint

Summary of Contents for HV2/210

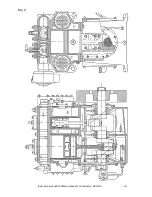

Page 16: ...Fig 1 Instruction manual for Water cooled Air Compressor HV2 210 15...

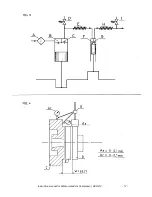

Page 17: ...Instruction manual for Water cooled Air Compressor HV2 210 16...

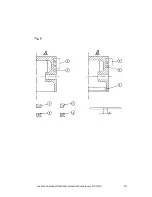

Page 18: ...Instruction manual for Water cooled Air Compressor HV2 210 17...

Page 19: ...Instruction manual for Water cooled Air Compressor HV2 210 18...