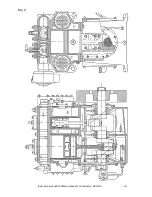

Instruction manual for Water-cooled Air Compressor HV2/210 - 7 -

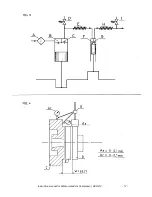

5.2. Valves

In the parts list and drawings each valve is shown complete, with its own part number, and also dismantled with

the part numbers of the individual components.

After overhaul or replacement of parts, assemble the valves in sequence as shown in the drawing of the

dismantled valve.

When assembling valves, lubricate the nut and valve bolt and tighten to the torques (in kpm) given below:

Dimension

Minimum

Maximum

M10

2.00

2.45

M12

3.60

4.40

M14

5.70

6.90

M16

9.00

11.00

IMPORTANT:

Before attempting to check compressor valves, loosen the clamping screw on the valve cover before removing

the cover.

After inspecting and overhauling valves, it is essential that the clamping screw, which bears against the valve

clamping piece and which keeps the valve in place on its seat, should be tightened with an unbrako key to the

torque shown in Table T.3.

Overhaul and mainenance of valves

Regular and careful maintenance of valves is essential to the capacity and reliability of the compressor. We

therefore recommend overhaul in accordance with the following guidelines:

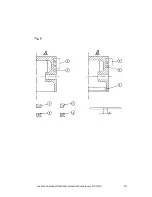

A. When cleaning and dismantling the valve, never clamp the valve directly in a vice to loosen the centre bolt

nut. A special clamping jig for this purpose, suitable for all valves, is available from the factory on request. A

simple makeshift for clamping the valve is to set it in a vice between two pins which fit into the outermost seat

slots of the valve.

B. Clean the valve components and check them carefully.

IMPORTANT

: Never use sharp implements on sealing surfaces and plate parts.

C. Replace all parts that are worn or even slightly scored. Check that all guide pins are in order. Maximum wear

limit is 10% of the total thickness of components.

D. If a valve spring or spring plate shows signs of weak-ness, all springs must be replaced at the same time,

because damage can result if some springs operate longer than others. Replacement of all valve springs is

recommended after about 5000 hours running time, even if the springs do not look worn.

E. If there are signs of abrasion or scoring of the valve seat sealing ledges, these must be machined. Most

valves are drilled for guide pins, with spare holes for new pins. Guide pins can be driven out by means of a

suitable tool. If it proves impossible to remove a broken pin, use one of the spare holes.

F. To remove the valve centre bolt, mark the centre of the pin with a centre punch and then drill out the pin.

Remove the centre bolt. After refitting the bolt, drill a hole for the safety pin, drive the pin securely into place

and peen the end to prevent it from falling out.

G. After completion of machining and careful replacement of guide pins in their respective holes in the valve

seating and/or catch plate, check that the ends of the pins do not but against the bottom of the holes in the

matching parts.

Use

only

genuine replacement pins and parts.

Assembly of valves demands precision, care and forethought. Make sure that the various parts are correctly

located and that the right numbers are installed. Compare with the lists and drawings of parts to ensure that the

right number of parts is present. Total lifting heights of valve plates are given in Table T.4.

Summary of Contents for HV2/210

Page 16: ...Fig 1 Instruction manual for Water cooled Air Compressor HV2 210 15...

Page 17: ...Instruction manual for Water cooled Air Compressor HV2 210 16...

Page 18: ...Instruction manual for Water cooled Air Compressor HV2 210 17...

Page 19: ...Instruction manual for Water cooled Air Compressor HV2 210 18...