Instruction manual for Water-cooled Air Compressor HV2/210 - 8 -

5.3. Lubricating oil system

The lube oil pump is a gear pump which is normally capable of operating for long periods without maintenance.

The pump is directly driven from the end of the crankshaft, and oil pressure is controlled by means of a by-pass

valve in the pump. To overhaul, dismantle the mounting flange and pipe connections, and pull the pump out.

An easily replaceable lube oil filter is fitted between the delivery side of the pump and the compressor.

IMPORTANT:

Accumulation of condensate in the crankcase may present a serious problem under certain

operating conditions, and it is important that the operator should check from the very beginning

whether condensate in the lubricating oil is liable to become a problem.

Unless the condensed water emulsifies with the lubricating oil, it will separate out and there is a risk that the

compressor will be lubricated with water.

The choise of lube oil is of great importance to the reliable operation of the compressor. The manufactorers have

performed extensive tests of lube oils for the oil companies, and the following is a list of lubricants recommended

on the basis of these tests.

A list of recommended types of oil is affixed to the compressor on delivery.

Mineral oil

Syntetic oil

BP ENERGOL RC 68

BP ENERSYN RX 100

CASTROL AIRCOL PD 100

CASTROL AIRCOL SN 100

CALTEX RPM COMPR. OIL 68

CHEVRON HD COMPR. OIL 100

ESSO/ EXXON EXXCOLUB 77

DAPHNE MARINE COMPRESSOR 100

FINA EOLAN AC

ELF PRIMERIA SG 100

GENERAL COMPOL A 100

ESSO/EXXON ZERICE S 100

MITSUBISHI COMPR. OIL 100

ESSO/EXXON SYNTESSTIC 68

MOBIL RARUS 427

MOBIL RARUS 827

NYNÄS COMPR. OIL 68

NIPPON OIL CO. FAIRCOL SA100

PHILLIPS COMPR. OIL 68

SHELL CORENA AP 68

SHELL CORENA P 68

STATOIL COMPWAY S 100

TEXACO SYN STAR DE 100

Further information about lubricants is available on application to the manufacturer.

5.4. Bearings

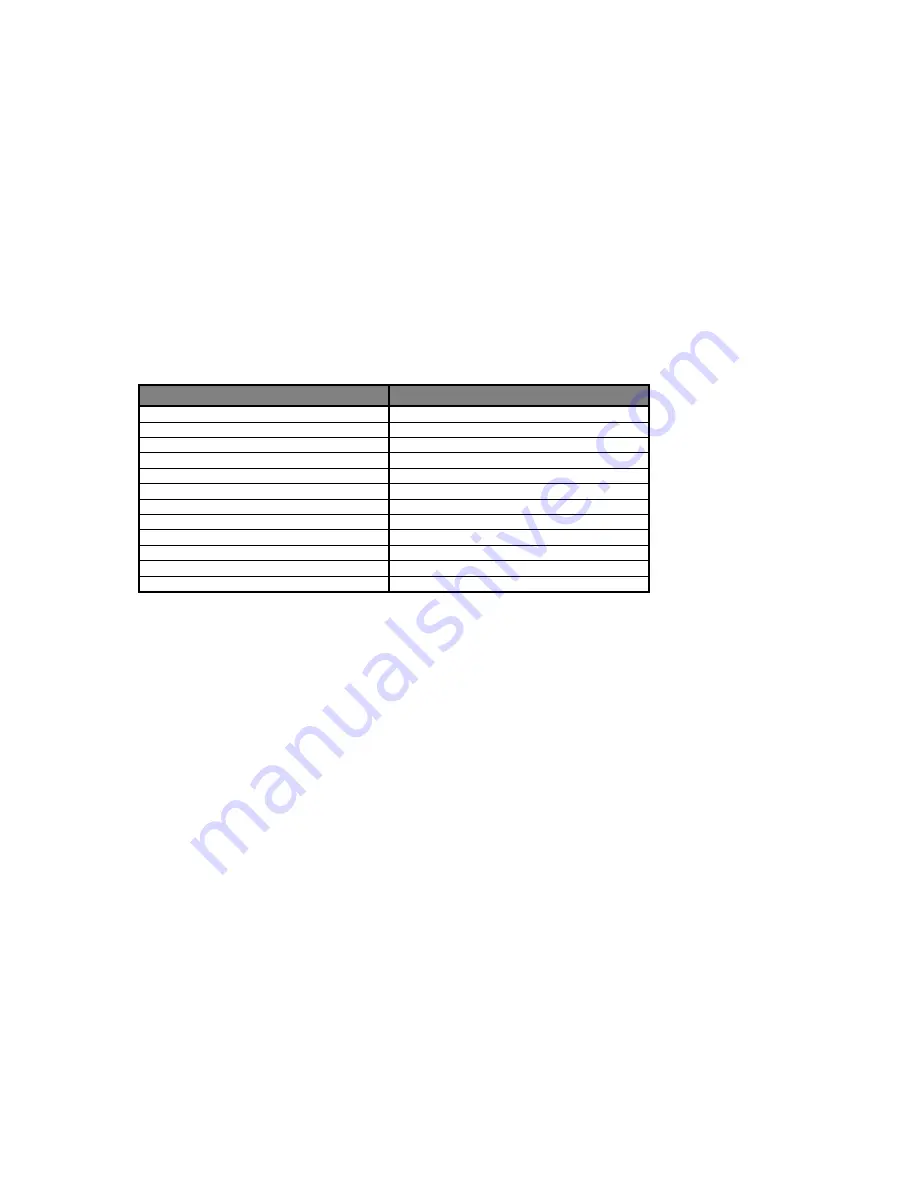

The compressor has replaceable, two-shell plain big-end and crankshaft bearings. The middle crankshaft

bearings serves as an axial guide for the crankshaft.

The gudgeon pin bearings are single shell plain bearings, press-fitted into the little ends. Tolerances and

clearances for connecting rod, crankshaft and gudgeon pin bearings are given in Table T.4.

All plain bearings are pressure lubricated.

After inspection or replacement of the big-end bearings it is important to ensure that the bearing does not bind on

the crankshaft. It must be possible to turn over the compressor manually.

New two-shell bearings are coated with a running-in compound at the factory.

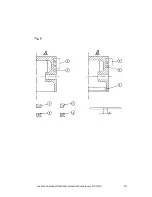

Dismantling the gudgeon pin bearing from the connecting rod.

A. Use a hydraulic press or extractor to remove the old bearing shell.

B. Press in the new bearing shell.

C. Adjust the fit of the bearing to the gudgeon pin in accordance with Table T.4.

Summary of Contents for HV2/210

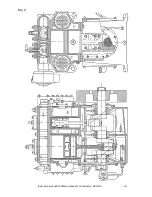

Page 16: ...Fig 1 Instruction manual for Water cooled Air Compressor HV2 210 15...

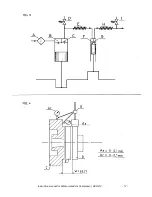

Page 17: ...Instruction manual for Water cooled Air Compressor HV2 210 16...

Page 18: ...Instruction manual for Water cooled Air Compressor HV2 210 17...

Page 19: ...Instruction manual for Water cooled Air Compressor HV2 210 18...