NGW 300 / LGW 300 / GBW 300

5 Troubleshooting and elimination of faults

501

5

Troubleshooting and elimination

of faults

5.1

General information

This section describes the troubleshooting and the elimi-

nation of faults in NGW 300 / LGW 300 and GBW 300

heaters.

ATTENTION

Troubleshooting and the elimination of faults require pre-

cise knowledge about the structure and the function of the

individual heater components and may only be carried

out by expert staff.

If there is any doubt, you can find out how the components

function in relationship to one another by reading sections

2 and 3.

ATTENTION

Normally, fault detection is limited to locating the faulty

components.

The following causes of faults are not taken into conside-

ration and should be thoroughly checked and/or a fault for

this reason should be excluded:

Corrosion of connectors

A loose connection on a plug

Crimping faults on connectors

Corrosion of pipes and fuses

Corrosion of the battery poles

After the elimination of each fault, a functional test must

be conducted in the vehicle.

5.2

General fault symptoms

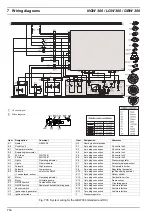

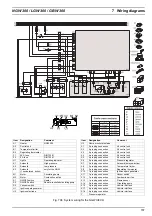

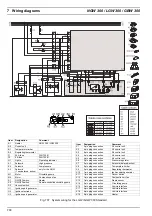

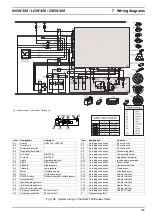

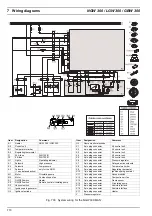

The following table (fig. 501) lists the possible, general

fault symptoms.

Fig. 501 General fault symptoms (page 1 of 2)

Fault symptom

possible cause

Electrical faults

The operating indicator light does not go on and the hea-

ter fails to function.

•

Inadequate voltage supply

•

Defective fuses

•

The line to the plugs of the control unit’s X2 connec-

tion is interrupted

The F1 fuse is activated.

•

Short circuit in the circulating pump or in the supply

line to the heater

•

Short circuit in the supply line to the heater/ motor

•

A defective operating indicator light or wiring to the

operating indicator light is interrupted or. shortcircuited

Faults in the water system

The heater ceases to function correctly, because the

connected heat exchangers are not delivering adequate

heat.

The flow rate is too low, because

•

there is air in the heater, in the heat exchangers or in

segments of the system

•

cocks (flow rate regulators) are restricted, dirty or

closed

•

there are impurities in the system, e.g. in narrow places

•

of the inadequate delivery rate of the circulating pump

(air in the pump housing),

Inverted rotational direction – check the

(cable colours(black + / brown –)

Inadequate anti-freeze protection,

The system resistance is excessive (particularly high

when cold)