NGW 300 / LGW 300 / GBW 300

6 Functional tests

601

6

Function tests

6.1

General information

This section decribes the tests on heaters in both their

installed and dismounted states to prove that they are

operating properly.

CAUTION

Heaters should not be operated in closed spaces such as

garages or workshops without an exhaust system.

Due to the danger of fire, do not switch on the heater if the

burner head is dismantled.

6.2

Combustion test

6.2.1 Test of CO

2

content

The CO

2

content in the exhaust gas must be measured:

–

as part of a function test

–

if there are irregularities in combustion

–

after the burner has been repaired

–

after the gas pressure regulator has been replaced

–

when refitting the delayed-action solenoid in the NGW

300 heater

–

when retrofitting NGW 300 and LGW 300 heaters with

an adjustable nozzle

–

for the operation of the NGW 300 heater with CNG

(natural gas) whose methane content is below 95 %

by volume

–

after the installation of a replacement burner

PLEASE NOTE

The CO

2

values for the NGW 300 replacement burner are

set at the factory for utilisation with the delayed-action

solenoid.

The CO

2

-content must be in the following range:

The NGW 300 heater and

the GBW 300 heater in the

NGW 300 version

8.5 to 10.5 % by volume

The LGW 300 heater and

the GBW 300 heater in the

LGW 300 version

10.0 to 12.0 % by volume

PLEASE NOTE

In heaters that have not yet been equipped with a gas

intake nozzle, no adjustment of the CO

2

-setting is

possible.

These heaters should be retrofitted with the adjustable

gas inlet nozzle, in order to set the CO

2

value correctly.

For heaters which are already equipped with the

adjustable gas inlet nozzle the CO

2

content can be set at

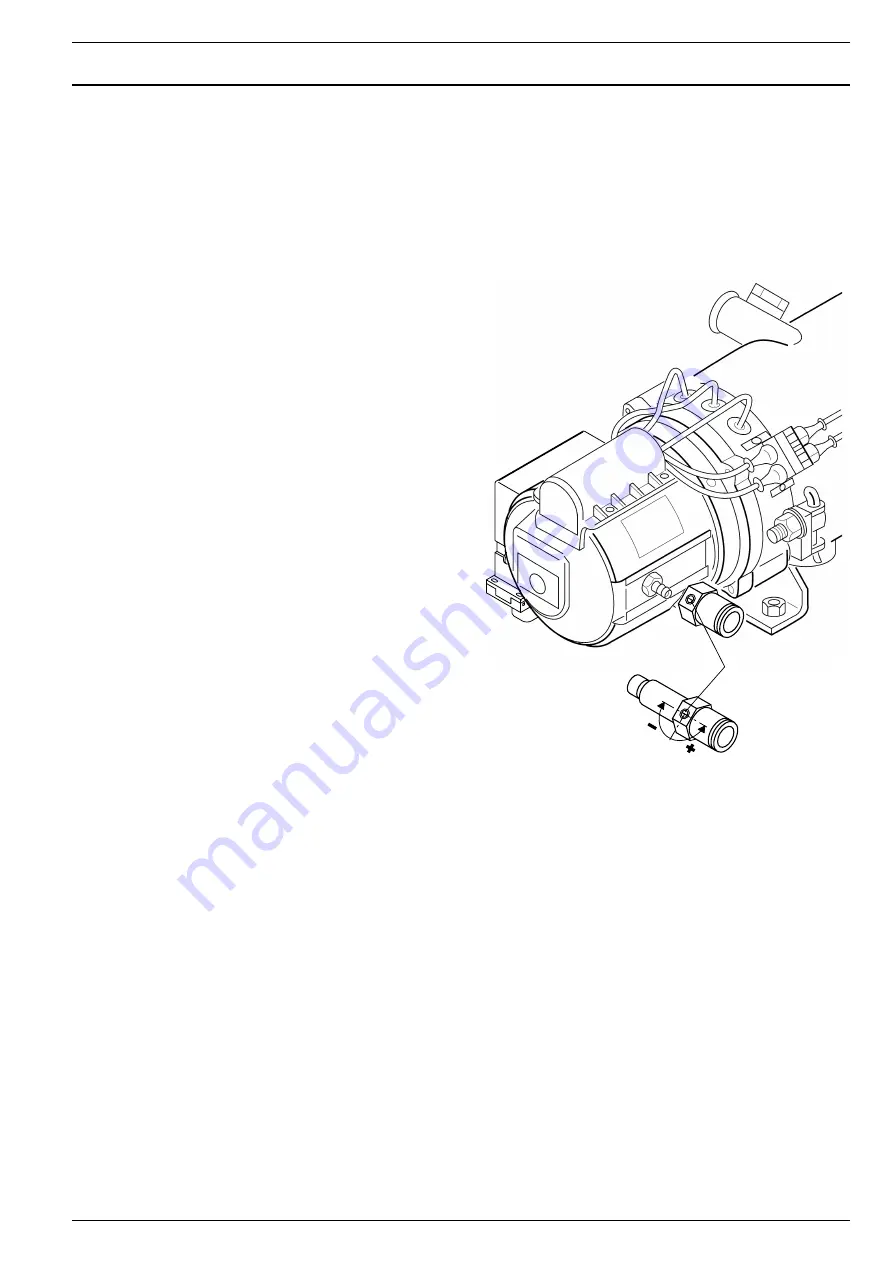

the setting screw (Fig.. 601).

The following tool is needed for this:

•

NGW 300

a 6 mm Allen key

•

LGW 300

a 4 mm Allen key

Fig. 601 Setting the CO

2

-content

Setting screw

CO

2

PLEASE NOTE

When setting the CO

2

, turn the setting screw carefully,

as even a slight turn will have a strong effect on the CO

2

-

value.