NGW 300 / LGW 300 / GBW 300

8 Servicing work

801

8

Servicing work

8.1

General information

This section describes the workwhich is permitted to be

performed on heaters when they are installed.

Work may only be performed on the heaters by staff who

have been trained by Spheros.

Work on the gas supply line and and on the gas pressure

regulator may only be performed by staff who are officially

entitled to do so.

Heaters must be protected against being wwitched on

unintentionally.

8.2

Working on heaters

The main battery supply must not be interrupted due to

the danger of the heater’s overheating and a related

activation of overheatingprotection, if the heater is in

operation or in the after-run.

When comprehensive repair work is being carried out on

the heater,it is advisable to dismantle it.

After work has been carried out on the heat circuit, a

coolant mixture of waterand antifreeze must be

replenished in accordance with the vehicle

manufacturer’s instructions and the heating circuit must

be ventilated.

8.3

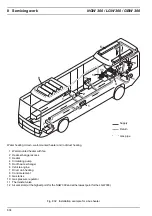

Working on the vehicle

ATTENTION

In the area of the heater,a temperature of 100 °C must

never be exceeded (e.g. when painting the vehicle).

8.4

A trial run of the heater

The heater may not be operated in enclosed spaces such

as garages or workshops without an extraction system

and may not be operated with time preselection.

8.5

Maintenance work

To ensure that the heater functions safely, the following

maintenance work must be carried out:

–

The opening of the combustion air intake grille and the

exhaust opening must be checked for dirt

accumulation and must be cleaned.

–

Outside of the heating season, the heater should be

operated when the vehicle’s engine is cold, approx.

every 4 weeks for

2

0 minutes, set at "warm" and

using the slowest fan level. In that way, starting

problems at the beginning of the heating season will

be avoided.

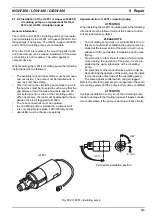

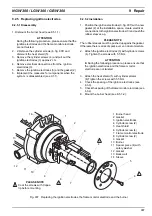

–

Every three months accumulated oil and condensate

must be drained in accordance with 6.3.8.5 at the gas

pressure regulator’s oil drain plug.

PLEASE NOTE

If no oil/condensate accumulation is visible, the draining

interval can be lengthened.

However, for purposes of verification, the draining

procedure must be carried out at least once annually.

–

The gas presure regulator must be replaced every 4

years for safety reasons (ageing of the seals).

ATTENTION

If solid particulate matter is found in the oil/condensate,

the gas pressure regulator must be replaced.

–

When renewing the coolant for the vehicle’s engine,

care must be taken to bleed the the heater, after the

vehcle’s cooling system has been bled. Turn on the

circulating pump (if there is a separate switch) or turn

on the heater for approx. 5 seconds and operate the

circulating pump in the after-run. This procedure may

have to be repeated. Insufficient coolant must be

replenished in accordance with the manufacturer’s

instructions.

PLEASE NOTE

The U 4851 and Aquavent 6000 S circulating pumps have

a dry running protection which deactivates the motor in a

dry run after approx.10 seconds in operating mode or

approx. 15 seconds after being switched on. The

Aquavent 6000 S shuts down only after 45 minutes,

when it is in a dry run.

The system is reactivated by disconnecting it from the

power supply for approx. 2 minutes.

–

At the beginning of the heating season, at the latest,

the heater and the gas pressure egulator must be

tested by a professional.